Cement cargoes are among those considered as a dry bulk trade that is extremely difficult to transport when needed in large quantities.

This is especially when the only available means of transportation is the conventional bulk carrier.

For that reason, effective and safe transportation of bulk cement would require the use of specialized cement trailers that can comfortably take large volumes of cement in perfectly sealed compartments to ensure secure and safe transportation.

When this operation is not conducted in the proper manner, the carriage may attract extra costs of cleaning and delays in between the transportation sessions.

Contact us, get more specs now!!

Table of Contents

1. How Many Ways to Transport Bulk Cement?

One. The bagged cement is mostly used in sites without dedicated mixing stations and storage bins.

The disadvantages are large dust and low efficiency and great harm to the human body. Additionally, they involve a lot of packaging work for transportation and unpackaging for use at their location.

All these processes also increase the overall cost of the cement. Although applicable for small projects, they may not suffice for big construction works.

Bagged cement transportation

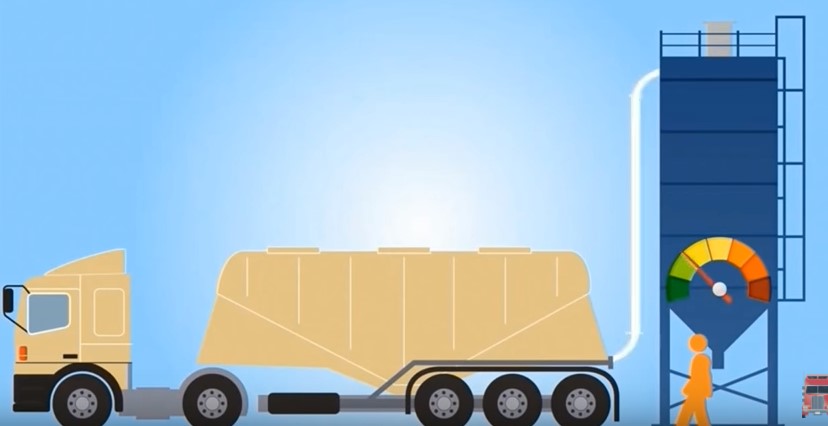

Two. Bulk cement. A bulk cement trailer can carry more than one hundred tons of cement.

At the site, the cement gets pumped through cement pipes by compressed air to a cement silo.

The main advantage of this transportation mode is that it is well SEALED hence will not leak. More than that, it offers easy transportation means especially for big projects that require huge volumes of cement.

Bulk Cement Carriage

Three. In addition to ordinary bagged cement, there is yet another form of the bag: one ton of packaging.

It is all handled by forklifts or cranes, not through manual means. It also avoids problems such as large amounts of dust. However, it is inefficient since it does not offer an optimum solution for different cement needs and requirements.

Ton Packaging

Four. In small-packaged bags of cement.

Where it is not possible to use such a large amount of cement in all some projects, small-packaged bags are used.

For example, if you want to build a pool at home, you need to use small packaged bags of cement. This ensures that there is no cement spillage and dust. Most importantly, it is easy to use.

Small packaged cement

Read More:

What is a powder pneumatic / bulk cement tank trailer?

Powder / Bulk Cement Tank Trailer Guide – How to Choose Specs/Capacity/Dimension

How Dry Bulk Cement Tanker / Pneumatic Trailer Works

2. What Should You Take Note of When Transporting Bulk Cement?

Bulk goods require a lot of care to ensure a safe transportation without incurring any loss or attracting additional costs that could otherwise have been avoided.

Cement is a very important product and for that matter, an expensive one whose mixture with concrete helps in the construction of strong structural members.

To maintain its qualities and value, it is important for it to be moved from its production plant to facilities for the ready mix.

In most cases, cement gets transported a number of times between production, terminal and ready-mix facilities.

Owing to the fact that cement is a fine product, a number of considerations should be made prior to and during the transportation.

Contact us, get more specs now!!

Failure to exercise good care of the product when handling and transporting it, damages can occur rendering it useless. Here are the three common issues that you should be aware of when transporting cement from one point to another:

2.1 Solidification

The fine nature of cement will make it harden should it be exposed to water making it wet. Should cement get wet in the course of handling and transporting it, it will definitely get hard and ineffectual.

For that reason, it is important to ensure that all vehicles and containers used for its transportation are entirely clean and perfectly dry prior to their use for the transportation.

Therefore, make sure that your truck, barge or railcar is free of any dampness or water.

Checks for any leakage signs should also be made, particularly when the transportation will be done through barge.

If this is not done, you will end up having unusable cement and become a financial burden to you.

A lot goes into the manufacturing of this valuable product and therefore, its transportation should be well-scrutinized to enhance its value and avoid losses.

wet cement

2.2 Contamination

During the transportation of cement, care should be taken to ensure that there is no form of contamination posing a threat to the purity and quality of the product.

If your carrier has some residue from the previously loaded product, there is a high chance that your cement will get contaminated.

Powder tank trailers especially are designed to carry many other products other than cement. Therefore, it is important to check it before loading a different product from the previous one.

In that case, the vessel that will be used for cement transportation should always be checked and cleaned to ensure that it is clean before placing cement in it.

When transporting cement through barge, it is important to get the services of a professional barge cleaning company to get the job done for you, at least to be sure that it’s properly done.

Contact us, get more specs now!!

2.3 Temperature

This is another important factor to consider when preparing to load cement for transportation.

Cement deteriorates easily at high temperatures. For that reason, cement being prepared for transportation should always be below 100 degrees Celsius prior to its loading onto the transportation vessel.

In the course of transporting cement, it is highly recommended to work with a company that has the skill and experience of doing so to avoid such complications and engage in safe transportation.

Take time to research on where you could get this kind of solution. Check online reviews and feedback from past customers to help you understand what you need and where to find help.

Contact us, get more specs now!!

2.4 Cement Transportation Procedural Checks

Highlighted above are the three common problems that may pose a threat to the safe transportation of cement.

Checks should, therefore, be conducted at each stage of loading and transportation to make sure that it doesn’t get affected.

cement tanker trailer loading

Taking note of each of the loading stages will help know where problems might have occurred in case of such an eventuality. In that case, here are procedural checks to do:

- Before Loading Checks

Prior to loading cement, its condition should be ascertained. The main issues that are common with cement cargo happen when the cement holds are not clean, dry and watertight.

Therefore, this must be checked before loading on any transportation vessel to avoid solidification and contamination by other products. Ensure that the load is within the desired temperatures before it can get loaded.

- Packaging

There are different forms of carrying cement. If it is not carried in bulk quantities, the shipping is usually done in 50Kg bags or paper. They could also be carried in one-ton polypropylene bags.

All packaging materials should be water-proof as absorption of carbon dioxide and moisture from the air can largely affect the quality of the product with time.

Cement can get deteriorated even without noticing it but its performance gets affected negatively as a result. Therefore, these checks should be thoroughly done to ensure that all goes well with the transportation process.

Contact us, get more specs now!!

- The purity of Loading Surfaces

To prevent contamination, it is important to make sure that the cargo holds are free from any smell and most importantly, they should be clean.

There are standard definitions on the level of cleanliness needed for the loading of cement for transportation. An independent surveyor can be hired to ensure that the vessel is in good condition to load the cement.

Residues from previous cargo should be thoroughly cleaned off to prevent contamination from them.

When cement reacts with raw sugar, even with very small particles, it gets affected seriously during setting and hardening in the projects for which it will be used.

Take no chances with this requirement because even the smallest contamination can ruin a whole load of cement. Actually, some cement companies will not allow their product to be loaded on vessels that previously carried sugar cargoes.

Tank inner clearing

- Checks from Production Line

Cement will be at very high temperatures after leaving the production line. A close monitoring should, therefore, be made to ensure that it is not loaded at such high temperatures.

Loading at the factory point is, therefore, a very delicate process that must meet all these requirements the moment cement goes through the kilns.

Hold coatings will get damaged when the product temperatures are more than 100 degrees Celsius. More than that, water vapour tends to form and dampen the cement rendering it worthless.

Pre-loading surveys should, therefore, be conducted to ensure that the cargo is within the recommended temperature for safe and secure transportation.

2.5 Desirable Conditions for Loading and Transportation

When the temperature of the incoming air is lower than that of the cargo in the vessels and cement holds, the ambient air cools and results into a vapour that will condense at some point.

This presents another situation where the solidification of cement could take place in the holds. In the end, the wet cement will dry and harden inside the holds before getting to the desired destination.

This will not only lead to losses but also to cleaning issues in preparation for the next load within the vessels. Therefore, it is important to ensure the following:

- Sufficient ventilation. This will help reduce the occurrence of vapour inside the cargo chambers. However, this to be permitted only when the weather is not overly humid.

- The temperature of the cement load can also be raised and end up damaging it as a result of the heat transfer taking place between the vessel and the fuel oil tanks. Highly viscous and low-quality dense fuel oil cannot be easily pumped at low temperatures and therefore, the heating of the oil is needed at such moments. The number of these tanks changes based on the type of vessel but in general, these fuel tanks are situated underneath holds. In the event that fuel gets overheated, the heat is transferred to the plating on top of the tanks all the way to the cargo holds.

The amount of damage caused depends on the moisture content of the cement cargo and the time taken for the heating process.

Contact us, get more specs now!!

This problem is commonly caused by the absence of communication between those in charge of the engine department and the deck department.

The engine department should be informed and be fully aware of the nature of load being transported. This will help them consider the consequences of any overheating that may occur on the fuel oil.

Overheating of the oil for the fuel may also result from incorrect operation procedures and the poor maintenance of steam valves.

When these are not closed fully, they may result in an unceasing flow of steam via the heating lines hence causing unwanted extended heating.

- Precautions can be taken with the use of special chemicals that could be applied to the cement holds prior to loading. These chemicals help in protecting the holds surface from the cargo and any subsequent cleaning procedure that may be applied. To attain the desired results, these chemicals should be used based on the directions and recommendations provided by the manufacturer since they can be difficult to clean and cause issues following a repaint on the holds.

2.6 Checks at Different Stages and Settings

Transporting cement safely depends on a number of things and for that reason, each stage counts towards its safe arrival to the desired destination.

The means of transportation also warrant specific checks to be done on it. Some cement transportation methods will need stricter measures than others.

- Working with closed loading systems

For closed loading systems, cement gets pumped under high pressure into the cargo holds via a loading chute as the hold covers are kept in a closed position.

Loading cement in this way may lead to a huge volume of cement dust sticking to the undersides of the hatch cover, the trackways of the hatch, the drain holes, hatch coamings and drain channels.

The use of incorrect loading equipment may even make the situation worse.

Failure to clean the cement dust leads to its hardening hence blocking the drain channels and holes once they come into contact with either seawater or rainwater in the course of the transportation process.

- Preparation for Departure After Loading

Before getting started with the journey once loading has been completed, the main deck, hatch coamings, hatch covers, draining channels and drain holes must be cleaned and washed down.

If the port allows based on their anti-pollution regulations, compressed air can be used to clean these areas.

In such a process, there will not be any loose cement on these surfaces that will harden on them following an exposure to water.

Contact us, get more specs now!!

- At the Point of Discharge

Check to ensure that the weather is good before making any cement cargo discharge from the transportation vessel. A letter of intent (LOI) should be provided if charterers insist to have the discharge made despite the conditions.

This would help in handling liability cases and serve to place all damage risks on the charterers. Ensure that everything at the discharge point follows the standard recommended procedure in order to take care of your products.

- Things to Do After Discharge

Once the cement has been discharged from the transport vessel, there will be pockets of remaining cement and dry residue loosely attached to exposed surfaces of the cargo hold.

This also includes attachment along bilge wells, hatch cover undersides, cargo hold bulkheads and hatch coamings.

The dust coming from the cement in all these locations must be cleaned using brushes, air guns and brooms using the help of Cherry Pickers where applicable.

Once all cement dust has completely been swept off, all these areas should get washed using seawater at high pressure of 2500psi.

high pressure water clearing

When you notice the presence of semi-hardened cement on the hold surfaces, you will need a more aggressive procedure to get them off right from the start.

Stiff bristle brushes alongside hand scrappers must be applied to remove most of the cement stuck on these walls.

When hardened, pressure hoses may not be in a position to effectively remove the hardened cement and in any case, they will make the situation worse.

Water will further facilitate the hardening of cement leading to more damage and increased delay in the cleaning procedure.

If you realize challenges in removing the hardened cement via sweeping and manual scraping of the surface, extra equipment like the high-pressure washers reaching to 20,000psi can be applied.

Contact us, get more specs now!!

That is how important the cleaning process is. The very high-pressure washers are costly and extremely heavy hence the reason you should be careful with all the other stages to avoid delay caused by the cleaning process.

The hard residues can still get tough for the high-pressure air and water equipment. In such a case, you will have to apply specialized machines and acid cleaners on the hold surfaces.

In the process of doing this, the acid could damage the hold painting and hence should be diluted using fresh water. Ensure that the hold paint is matched with the correct acid cleaners as recommended by the manufacturer.

There are checks all over and therefore, you must ensure you get each one of them right at every stage. Acid cleaners should be applied with a lot of precaution since they can harm the people doing the cleaning.

Consultations with the material safety data sheets should always be made to ensure safe cleaning procedures. Make sure that any loosely attached cement residue on the exposed surfaces of the cargo holds is swept away after each discharge.

3. The advantage of Cement Tank Trailer in Bulk Cement Transportation

The cement tank trailer is a tank trailer used for the transportation of powdered products.

The vehicle is constructed of specially design chassis, tanker, pneumatic piping system and cargo discharging units.

This type of trailer is used to carry any powdered cargo and cement is one of them. It is well-customized to ensure the safe transportation and delivery of bulk cement from the production factory to the desired destination.

Generally, the tanker trailer is designed to take up any powered product with particle diameters of less than 0.1mmm.

The demand for cement and volumes needed for different construction projects warrants the use of a huge transportation vessel in the nature of a tank trailer.

For easy and faster movement of cement within and from a manufacturing factory, cement warehouse and to construction sites, this is definitely the type of vessel you need.

Practically, the time taken to package and discharge the cargo is highly reduced. More than that, there are also cost benefits that come with the use of a powdered/cement tank trailer.

It is the best vessel for carrying bulk powder cargo such as cement. Ideally, the tanker is not designed for the transportation of one type of product.

cement tanker

When not using it for cement transportation, it can be used for transporting such powdered products such as sugar, lime powder, flour, lime powder, chemical powders, fly ash, stone powder and mineral powder among others.

When needed for transportation of cement, the cement tank trailer will be most applicable in cement factories and in large construction sites and warehouses.

To function, the tank trailer makes use of compressed air in the cement discharging process from the holding chamber. This type of tank trailer comes with a lot of benefits.

Structurally, they are pneumatic tankers with in-built vacuum-sealed and enclosed chambers used for the safe transportation of your cement without affecting its quality.

Here are some of the key advantages that come with the use of a cement tanker trailer.

- Easy to Work With

The cement tank trailer is a lot easier to work with especially with the loading and offloading processes.

Compared to other conventional ways of transporting cement, the time taken to load and offload cement cargo is greatly reduced.

This is a possibility due to the installed pneumatic system that helps in largely reducing the time taken between the transportation trips.

- Safe Vacuum-Sealed Holds

This type of tank trailer provides a vacuum-sealed tank for carrying cement. With this setup, there is no entry of air that may dampen the cement.

This helps in retaining the quality of the cement and in delivering it as a useful product just as it was from the cement manufacturing plant.

With this tank trailer, no germs, moisture or germs can find their way inside hence the cargo remains free from contamination.

- Simple and Convenient

A lot of conveniences comes with the use of the cement tank trailer in that it can help you transport large quantities of cement at ago.

This happens without any concerns of tampering with the quality of the cement because a standard procedure is applied in ensuring that the cargo is loaded in good conditions.

Again, there is no much of cumbersome packaging and unpackaging of cargo between the factory and offloading points. The offloading process is highly simplified with the use of a fluidization procedure that uses an air compressor and fluidized bed.

Contact us, get more specs now!!

- Efficient Delivery Speeds

Looking at the nature of operations with a cement tanker trailer, the rate at which cement is transported and delivered is high.

Most importantly, large volumes of cement can be taken at a moment saving on the time that would have been used when transporting the cargo via different cement bags.

There is a lot of efficiency in terms of costs due to the quick delivery procedures applied. Conventional cement transportation processes lack efficiency that can be provided with the use of a cement tank trailer.

- Sufficiently High Load Capacity

The transportation of such products as cement requires high loading capabilities that can guarantee the safety of the product during the transportation process.

A standard cement tank trailer has a load capacity of 95 cubic meters in a set. This gives you a perfect solution when in need of transporting high cement volumes as would be needed for use in different projects.

- Human Safety

Those working with the cement tank trailer having nothing much to worry about as far as their health is concerned. There is no or minimal dust that comes from this kind of operation.

Ideally, it is because of the minimal human involvement in the loading and offloading of cement on and from a powdered tank trailer.

Cement dust

The benefits are even many with the lifting type of cement tank trailer.

It provides you with a single storehouse-like structure that can take a considerably high amount of cement and be handled through mechanized ways limiting human involvement.

As a result, the offloading operation becomes a lot simple. The discharge speeds that are usually slow with human involved are greatly reduced to just a fraction of that time.

Now that the discharge is done pneumatically, the residual materials are very little making it easy for the after-discharge cleaners to prepare the trailer for the next trip.

Most importantly, the internal structure is very simple and makes the disassembling and cleaning of the fluidized bed a quick and convenient procedure.

Contact us, get more specs now!!

4. Conclusion

There is a lot to be put into consideration in your choice of the means of transporting cement from one location to another.

First, you must establish the quantities needed before settling on a particular type of vessel for your transportation needs. There are different cargo vessels designed for unique applications.

If you are handling large volumes of cement, consider going for the powder tank trailer that can take up a lot of cement in one trip. You will save a lot of time and costs involved in such operations.

A safe and secure transportation of your cement cargo should be administered carefully especially when dealing with large volumes of cement.

Make sure all procedural checks are conducted before loading, during loading, transportation and discharge of cement.

Most important to check is to ensure that your cement is free from elements that can make it solidify or get contaminated.

If you are taking the cement directly from the production line, it is important to ensure that it is loaded at the right temperatures desirable for transportation.

Any overlook on these requirements may turn out to be consequential. Therefore, it is important to adhere to them and where possible engage the services of a professional to get everything done as recommended.