A bulk tank trailer is a type of tank trailer that is used in the transportation of bulk powder such as flour, cement and chemical powder among other similar products.

It is constructed of combined chassis structure that comes with a tanker, a piping system and a number of discharging units. The design takes into account the safe loading and transportation of bulk powder products.

Products carried by the bulk tank trailer have a particle diameter size of <0.1mm. It is commonly used in the cement manufacturing industry for the transportation of cement to construction sites and storehouses.

The bulk tank trailer has one huge advantage: the costs of loading products and discharging them are largely reduced.

Read More:

Powder / Bulk Cement Tank Trailer Guide – How to Choose Specs/Capacity/Dimension

Table of Contents

One: Basic Operations of the Bulk Tank Trailer

To load and discharge products from the tank trailer, a fluidization principle is applied. This is what lies behind the working principle of a bulk tank trailer.

Through it, the powder products can easily be loaded and unloaded from the bulk tank trailer making the process efficient and fast translating to savings in the operation costs:

- Fluidization Principle

A powder acquires some liquid properties on exposure to gas at certain levels.

In fluidization, the process is comparable to a liquefaction process where granular materials are converted to dynamic fluid-like conditions from their initial static solid state.

This usually happens when gas is passed through the granular material.

Gas gets introduced through the bottom section used for transporting the solid particles causing it to move in an upward manner through the bed into the empty spaces between the particles.

With low gas velocities, the aerodynamic drag on the particles is also low, which allows the bed to stay in a fixed state.

During high velocities, the aerodynamic drag forces oppose the gravitational forces and counteract to make expand the bed volumetrically while the particles start to pull away from each other.

As velocity continues to increase, the critical value will be attained when the upward drag forces are the same as the downward gravitational forces.

Here, the particles will now be in a suspended position within the fluid. At this point, the bed is said to be fluidized.

When the fluid velocity is increased further, the bulk density of the given trailer bed starts to show fluidic behaviour.

With time coupled with increased fluid velocity, the bulk density of the trailer bed will keep reducing leading to a more violent fluidization.

As this continues, the particles will no longer form a bed and will instead be taken in an upward manner following the gas flow. Upon a full fluidization of the bed, the solid particles will begin to flow like a fluid.

Two: Various Bulk Tank Trailer Structures

This type of trailer comes in different types primarily based on the structural configuration. Different conditions of work will require different types of bulk tank trailers.

Therefore, buyers should consider all options before settling on one particular type. Operations take place at different places with different terrains and so on. The terrain, for instance, can define the type of tank trailer to buy or hire.

A number of factors come into play even as you choose the type of tank trailer to use. Stable ones can get you low insurance premiums because the transportation risks are kept at a minimum.

The efficiency of your operations is thus enhanced both from a financial perspective and again looking at the work aspects.

Each of these structures is particularly suited for a particular type and weight of cargo. Here is some detailed information about the types of bulk tank trailers you will find in the market:

Read More:

How Dry Bulk Cement Tanker / Pneumatic Trailer Works

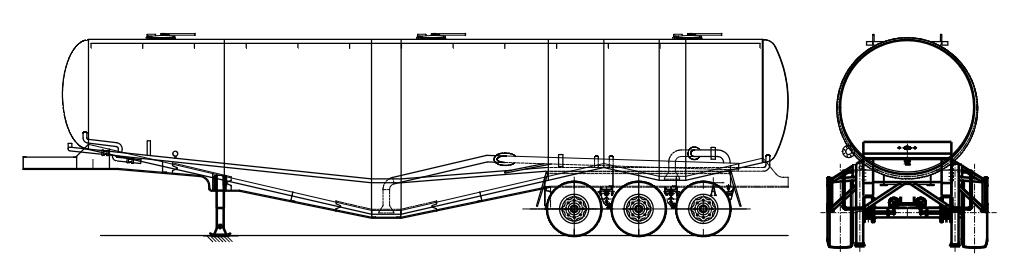

2.1 The Horizontal Type

The design of the horizontal bulk trailer is made with a low center of gravity that enhances its stability. It has a much bigger volume than other tanks in this category.

Most tanks with a horizontal structure have a single compartment. Therefore, it takes a shorter time to build the gas pressure needed. The discharging process is also faster.

Generally, this type of tank is easy to operate.

However, this type of tank only adopts a pneumatic discharge. It is not perfectly efficient because all the powder is not always discharged out of the tank.

In that case, it is unlikely that any other material type will be transported through the same horizontal tank trailer. In most cases, it is used for transporting fly ash and cement.

2.2 Funnel Type

The funnel type of a tank trailer can take a wide range of materials more than the horizontal type can. The materials can either be in powder, granule or massive.

For the granule and powder form materials, pneumatic discharge can be used. The massive materials are usually discharged into a designated pit by means of tipping using gravity.

The cone bus bar and the horizontal plane are usually set at 45° or more. That means that the powder will be in a position to slide directly to the fluidized bed.

With the design of the tank trailer, it is unlikely that there will be residual substances left in the tank trailer following a discharge. This type of trailer is commonly used for the transportation of powder chemical and flour materials.

2.3 Tilt Tank Trailer

The tilt tank trailer is a very durable tank trailer because of the way it is built to function and operate.

Again, it has enough storage space. They can be used for various cargo materials with heavy steel and aluminium construction options to choose from based on the kind of products you want to transport.

The lifting type of tank trailer comes with a lot more advantages than the other types of tank trailers. By simple definition, the lifting type can be described as a single storehouse structure.

The tank assumes a big angle of tilt once lifted. This makes the unloading operation easy and quick. Those seeking for fast discharges especially where there is a lot of powder materials to be transported can rely on tilting tank trailer.

With this tank trailer, you can transport various types of powdered materials and that includes powdered products, granule materials and even block products.

Discharge can be made via pneumatic means or through gravity tipping. In this setup, the fluidized bed is a small section and that means there aren’t much of residual products left on the surface of the tank trailer during unloading.

The internal structure configuration is also very simple making it a reliable tank trailer to work with. As a result of this, the disassembling and cleaning of the fluidized bed is really quick and convenient for all users.

The ability to change from one particular type of load to another makes it most suitable for use in many operations.

Three. The Basic Specifications of a Bulk Tank Trailer

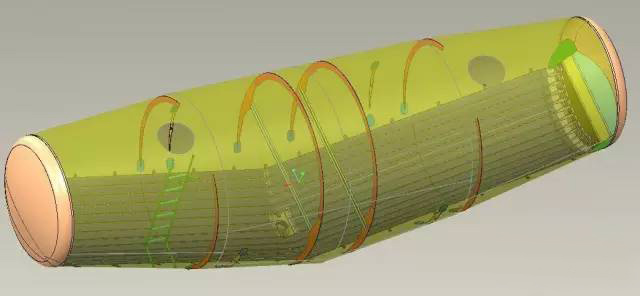

The bulk tank trailer as described in here comes with a number of capabilities. It is basically a rigid construction made of high-grade material A572Grade 50 (Q345) able to withstand the load and forces during transpiration.

There are some especially the horizontal type with only one compartment but others can have even 4 compartments.

An air compressor is also available to facilitate the fluidization process for the loading and discharge of materials being transported. Here are other specifications associated with the bulk tank trailer:

| Dimensions | Based on Capacity |

| Capacity | 30-80cbm |

| Compartments | 1-4 |

| Tank Material | A572Grade 50 (Q345) |

| Tank Thickness | Tank 4 mm, End Plate 5 mm |

| Manhole | 2-5 Optional |

| Air compressor | 10, 12, 14 m³ cylinder (optional) |

| Diesel Engine | Optional based on demands |

| Axle | Optional 2 or 3, different capacity |

| Suspension | Leaf Spring or air suspension (optional) |

| Tire | Optional |

| Wheel Rim | Optional |

| Landing gear | Optional |

| Brake Chamber | Optional, ABS system |

| Discharging pipe | 6m*1 piece |

| Remarks | Pressure: 0.2Mpa

Discharge Rate≥1.5T/min Vertical feed height≤35m Residual rate≤0.3% |

Read More:

What is a powder pneumatic / bulk cement tank trailer?

3.1 Diesel Engine and Compressor

The diesel engine is the main power unit supplying all the needed power to tank trailer.

For bulk tankers with a capacity of 45 cbm, they will need a 36-50kw diesel engine and an air compressor with a rated displacement of 12m3/min.

The air compressor is very useful in the fluidization process that makes this type of tank trailer unique from all other types of tankers.

The engine is a 4 cylinder combustion diesel engine that is used to provide the power needed to drive important parts of the bulk tank trailer such as the air compressor.

The engine is sourced from a reliable brand to ensure reliability and efficiency during the transportation of powder materials from one location to another. Here is a summary of some of the key specifications of the diesel engine:

| Name of Product | Diesel engine ZH4102P |

| Type | Combustion Engine |

| Cylinder number | 4 |

| Ignition Mode | Compression-Ignition |

| Fuel | Diesel |

| Displacement (L) | 3.76 |

| Cylinder Arrangement Form | L |

| Rated net power/Rotation speed(kW/rpm) | 36-50/1800-2200 |

| Starting Method | DC12V Electric Start |

| Piston Movement | Reciprocating |

| Emission stage | In compliance with StageⅢ in GB20891-2014 |

| Intake Pressure Impulse | Naturally Aspirated |

| Net weight(kg) | 480 |

| Application | Bulk material semi-trailer |

| Name of product | HYCW-12/2 12CBM dual cylinder air compressors for bulk tank trailer |

| Outsize | 951*930*775 mm |

| Rated displacement | 12m3/min |

| Rated discharge pressure | 0.2MPA / 2 bar |

| Power | <=37Kw |

| Rotating speed | 1000r/min |

| Intake air temperature | <=40℃ |

| Exhaust gas temperature | <=200℃ |

| Cooling method | Air cooling |

| Weight | 385Kg |

3.2 Material and design

The bulk tank trailer is of a stainless steel construction making it resistant to attach by rust. Therefore, there is a guarantee of long life.

However, it may not carry as much product as an aluminium alloy tank trailer would due to weight restrictions by local laws and regulations.

There is also an aluminium alloy bulk tanker option that is light in weight, making it a more economical option to go for. Aluminium alloy is always used to transport chemical powder and flour.

If you are looking for a bulk tanker to transport cement and construction powder, then the option constructed of mild steel is the best option to take.

3.3 Capacity

Your choice of bulk tank trailer will also be informed by the amount of product you want to transport. Large volumes would require a high capacity tanker and vice-versa.

In that case, there are tankers ranging from 25cbm to 80cbm.

An important aspect to note is that, when the capacity is more than 60 cbm, a different construction material and structure will be used to enhance strength and stability in operations.

For example, the Horizontal Type needs to have a W structure. Again, it will require a more firm material.

3.4 Safety Parts

To enhance efficiency and safety in operations, the bulk tank trailer is usually fitted with the following safety features:

- A pressure gauge that helps to track the inner pressure of the tank

- A Safety valve or Pressure valve that ensures that the pressure of tank is in a safe range

- A Blowing aid pipeline that contains air coming directly from the air the compressor. This prevents any material from getting stuck in the outlet pipeline.

- A Check valve that ensures that the compressed air has no reflux hence avoiding accidents

Conclusion

The bulk tank trailer is a very use tanker custom-made for powdered products. It helps in the efficient transportation of such materials as cement, flour, chemical powder and many similar-like products.

It is the safest, quickest and effective ways to transport powdered products with minimal or no residual products left on it.