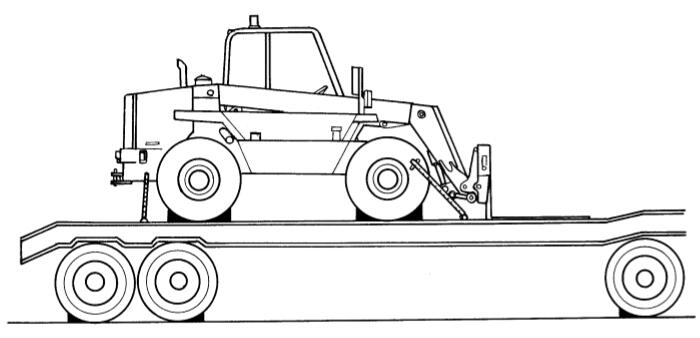

The detachable Gooseneck lowboy trailer also known as the removable gooseneck lowboy trailer is a vehicle used for carrying heavy cargo.

It can be used for loading and transporting heavy machinery and equipment. The removable gooseneck trailer is a hydraulic assembly that has a trailer bed and a gooseneck connected in a way that they can be detached from each other.

What is The Difference between Removable Gooseneck Trailer and Folding Gooseneck Trailer

Low Bed Trailer Ultimate Guide – What is a Lowboy/Lowbed Trailer?

1. Lowboy Trailer Structure Configuration to Function

The lowboy detachable gooseneck trailer is particularly adapted to carry and transport large mobile equipment. It is able to do so due to its low-level trailer bed or frame and its gooseneck feature.

Most important to note is that, the trailer bed has backwardly placed moving wheels.

Here are the most important parts that enhance your operations with a lowboy trailer.

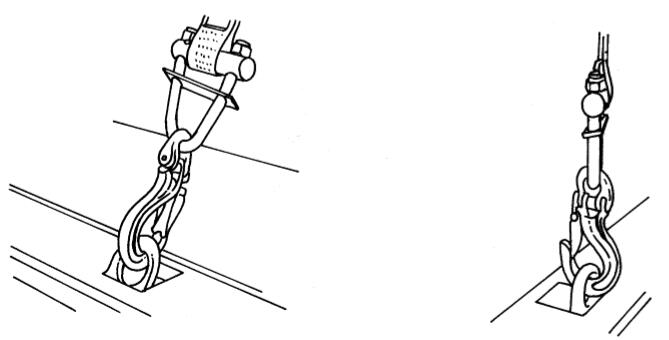

First, there are two interlocking pairs of the main coupling hooks.

Lowering and raising the trailer assembly is made possible through the use of synchronized hydraulic ram. These operate in between the trailer bed and the gooseneck at a point towards the back of the coupling hooks point.

There is also a pair of thrust load bearing blocks together with a pair of safety hooks normally engaged in between the trailer and the gooseneck.

This is to keep them in a good operating position. To keep the main coupling hooks in a good interconnecting relationship, a pair of coupling lock pins is used.

Additionally, there is a retractable safety pin that is used to maintain the interconnection in between the trailer bed and the hydraulic ram attachment of the gooseneck.

The ram features offer a positive lock of thrust power load bearing blocks perfectly in a load bearing state when in a normal operation.

The control attachments for the trailer assembly components are well placed on one part of the assembly to enhance safe operating procedures.

Contact us, get more specs now!!

2. Loading Differences from Common Lowboy Trailers

The main difference between loading removable gooseneck lowboy trailer and common lowbed trailers is that, the removable gooseneck trailers load the equipment or cargo from the front.

Ideally, the removable gooseneck trailers are complex to operate, but the equipment/cargo is easily driven on the trailer. The equipment is more safety and stable during loading, transit and offloading operations.

Unlike a detachable gooseneck lowboy trailer, a common lowbed trailer is loaded from the rear section. Essentially, the equipment should be driven on the trailer through ramp of low bed trailer.

This provides a simple operation but the equipment or whatever cargo carried on it needs to be careful to drive on the trailer.

3. Lowboy Trailer Design Features and Operation Dynamics

When the trailer assembly is taken back to its operating position ready for towing, thrust power load bearing attachments particularly in the nature of blocks are located in between the trailer bed and gooseneck rearward of the main coupling features.

This is meant to take sufficient thrust weight or compression loads between the trailer bed and the gooseneck in that position in order to create a force couple through the coupling features and keep the trailer bed and the gooseneck in their exact relative position.

The trailer comes with a detachable link in the nature of a retractable pin to link up the ram feature to the trailer bed.

Once the blocks are in their thrust power bearing point, the ram feature is pressurized to draw back and exert a force in between the trailer bed and the gooseneck via the thrust blocks to enhance more reliability and safety during travel induced shocks and vibrations.

Transporting bulldozer by detachable goosneck trailer

Safety is vital these operations. For that matter, safety hooks are made available to interconnect between the trailer bed and the gooseneck within the region of the thrust blocks.

Actually, both the thrust blocks and the safety hooks are rotate-ably mounted on the same shaft or be made available as a unitary member to move it simultaneously in and out of the operating point.

The main coupling hooks come with lock pins that can retract. This helps in keeping the coupling hooks in an accurate inter-fitting connection with the trailer assembly during operation.

The main link or coupling between the trailer bed and the gooseneck via which the fundamental towing forces are transmitted via the gooseneck to the trailer frame includes a pair of upturned gooseneck hooks that are laterally spaced located at the lower front end of each of the gooseneck upright members.

There are other two matching in a downwardly facing bed hooks at the farthest end of the trailer bed. A relative rotational movement of the trailer bed and the gooseneck is caused by a pair of hydraulic rams that are laterally spaced.

Each of these ram feature is installed with an upper hydraulic cylinder and a lower piston rod.

The cylinder’s upper end of each of these rams is pivotally linked with an anchoring member which is basically a cross member located at the upper back end section of the gooseneck.

The lower ends of these two piston rods are connected rigidly to the same T-bar yoke.

This T-bar yoke is an important feature that transmits the thrust loads from the rear section of the gooseneck to the trailer frame at a point backwardly of the main link.

The T-bar yoke being firmly connected to the piston rods offers a unitized ram feature that has an equal force from each of them.

The trailer is also installed with a hydraulic pump to provide fluid to the ram features and with a small internal combustion engine needed to power the pump.

These are usually situated at the upper rear part of the gooseneck under the cover doors. Most of the control components that need access to facilitate operation are located on the left part of the trailer assembly.

Removable Gooseneck Structure

Reference:

Contact us, get more specs now!!

4. How to Detach the Removable Gooseneck

Removable gooseneck lowbed trailers are of many types. However, most of these removable gooseneck’s operation principles are the same. When detaching your gooseneck trailer, here is a standard procedure to follow.

- Step 1: Remove the locating pin as well as the air tube and the electric wire connections

- Step 2: Lower the cargo bed once all the linkages have been securely removed

- Step 3: Drive off the truck together with the gooseneck away

- Step 4: Once the truck has been driven off, loading can now take place comfortably from the front of the trailer bed.

The main purpose of detaching the gooseneck from the trailer bed is to allow the equipment to be loaded and offloaded over the front section of the trailer frame or bed.

In this case, the loading height can be adjusted to become as low as possible, say 6” as the trailer bed’s forward end leans on the ground.

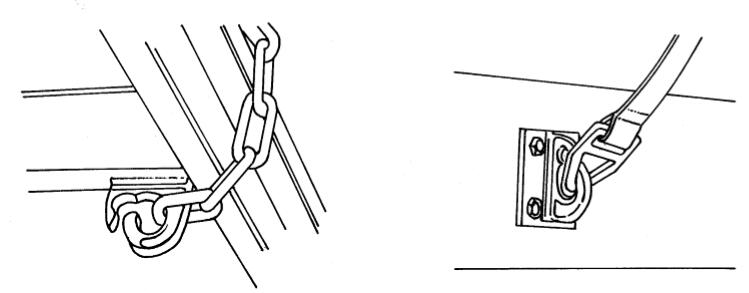

Securing the Cargo in Place for Transportation – Once the cargo has been loaded on the trailer bed, it should be safely secured in place ready for transportation. In that case, you should ensure to fix the cargo by ropes, nets, chains.

5. Detailed Operations to Facilitate Lowboy Trailer Loading

There are the major force-transmitting regions of a lowboy trailer. One of them is the main coupling responsible for transmitting the fundamental longitudinal towing forces between the trailer and the gooseneck.

This coupling works as a single point in a force couple to keep the trailer frame and the gooseneck in their desired relative positions.

There is yet another force vector of the same force couple usually transmitted through the thrust blocks in the back of the gooseneck. This essentially is a bearing surface of the trailer frame at a point spaced backwardly.

Hydraulic pressure is then supplied to the bottom part of the ram cylinders to facilitate the retraction of the rods.

This creates a hydraulic lock between the trailer bed and the gooseneck. A lock pin is then used to make a positive link between the yoke pocket and the T-bar yoke.

Generally, this forms a positive connection from the yoke pocketed located in the trailer bed frame to the hydraulic ram anchor feature of the gooseneck.

The effect caused helps in holding the thrust blocks tightly in position.

The safety hooks are engaged safely with their respective pins and the lock pins are used to keep the two key coupling hooks in a tight inter-fitting connection to prevent any accidental release.

Contact us, get more specs now!!

- Uncoupling for Loading

During coupling and uncoupling, the trailer assembly is let to a lowered position. During uncoupling, the safety pin handle gets puled and locked open to let the safety pin detach the T-bar yoke free from the yoke pocket.

The control lever for the hydraulic ram feature on the other hand is maneuvered to provide hydraulic pressure fluid inside the dram in order to lift the thrust blocks somewhat clear off their sitting positions on the main beam.

After achieving this, the lock finger gets retracted and the crank handle then is swung in an upward manner to anchor the safety hooks and the thrust blocks upwardly.

Once this is attained, the lever is then locked in position through the lock finger that is fit in an upper coupling hole for the same.

Next, the hydraulic ram feature gets extended further to facilitate a further gooseneck rotation with respect to the trailer bed. This is done to facilitate the withdrawing of the two lock pins that are engaged with the hooks.

The pins get swung in an upward manner through the use of the crank handle. On achieving this, the hydraulic pressure in the ram gets reversed hence allowing the pressure to go down in the cylinders’ bottom chamber.

This action slowly lowers the gooseneck and the trailer bed to the ground. You can choose to place a removable support block in between the trailer frame and the gooseneck beam in order to keep the gooseneck slightly off the ground surface.

It is at this point when you can move the tractor away in order to give room for loading.

- Coupling for Transportation

Once your cargo has been safely loaded on the lowboy trailer bed, it is time to reconnect the gooseneck and the trailer bed ready for transit. Basically, this is a reverse procedure of the uncoupling operation.

First, the operator needs to reverse back to the trailer bed location. Ensure that the coupling hooks are set in position to facilitate easy engagement.

The forward section of the trailer bed has a forwardly swerving entryway to make the hooks align with their attaching positions.

When the T-bar yoke is perfectly aligned with the yoke pocket, fluid pressure can now be supplied to the hydraulic cylinders’ top chambers.

This forces the piston rods downwards hence driving the T-bar yoke directly into the pocket. The safety pin is then inserted to ensure a positive link between the pocket and the T-bar yoke.

More hydraulic pressure is supplied into the cylinders to move the trailer bed and the gooseneck in an upward direction.

The trailer bed should be moved to reach a position higher than its horizontal operating level to facilitate the moving of the lock pins into their perfect locking position.

Once this is achieved, the hydraulic rams are then retracted back to allow the trailer bed and the gooseneck to descend.

The next thing is to move the safety hooks and the thrust blocks downward into an engaging position to lock them in place. After that, the fluid pressure in the rams is then reversed moderately.

This provides a hydraulic interlock that holds the thrust blocks tightly in place. Once this is done, the trailer assembly is now ready for over the road transportation.

Contact us, get more specs now!!

6. Important Considerations

One. Should the trailer assembly approach a low overhead obstruction such as a bridge, your operator should lower the assembly moderately by simply releasing the trailers’ hydraulic rams.

On the other hand, when approaching a raised road obstruction like an exposed railroad track, the compression blocks and safety hooks can be let loose and then extend the hydraulic rams to a desired position for a slow speed over a short distance in these scenarios.

Two. When there is a need to detach the gooseneck from the tractor to keep the gooseneck still attached to the trailer frame. Engage the safety hook with pins to hold the gooseneck in position and prevent it from falling in a forward direction.

To add on this action, you can also engage the T-bar yoke with its pocket. It will also be important to maintain the pressure in the base chamber of the hydraulic cylinders to keep the gooseneck in position in a way that it cannot fall forward.

However, you can move the gooseneck in an upward or downward manner by way of retracting or extending the hydraulic rams.

For this position, the separate landing jacks should be left under the trailer to keep it from dropping to the ground surface. You could also leave the gooseneck attached to the trailer through hydraulic means.

All you need to do is to remove the safety hooks together with the thrust blocks and leave the pin in position. After that, retract the hydraulic ram to a point where the trailer frame touches the ground surface.

All pressure should be removed out from the fifth wheel plate. The fifth wheel king pin can then be let loose and then the truck be driven off.

To ensure safety, the thrust blocks and safety hooks should be taken back to their operative positions. This way, the gooseneck will be self-anchored on the trailer even when the hydraulic pressure is lost.

Conclusion

The lowboy detachable gooseneck trailer is a perfect vehicle used in the transportation of heavy machinery and equipment.

The gooseneck has a forwardly extending frame that has two firmly linked main longitudinal beams and a back portion with two upright members firmly linked to the back end of the two beams.

For a loading position, the gooseneck needs to be detached from the from the trailer bed and the truck driven off to give room for loading cargo.

Loading is usually done from the front end. This is a basic understanding of how the lowboy trailer operates to help you load and transport your cargo.