Regulations by the governing authorities around the world define the maximum load that can be carried on transportation infrastructure.

Exceeding the limits set can attract heavy fines that you would not want to incur as a logistics company. As a result, many people end up carrying less cargo than they would have wished to carry.

That reduces the efficiency of the transportation process since you will be forced to take more trips for what could have been transported in few trips.

So, where is the solution to this kind of situation? How can you carry the maximum load and yet not breach the set rules and regulations on heavy cargo transportation? The solution lies in the building of lightweight transportation vehicles.

In the oil and gas industry, the same case applies. If you want to take in more cargo and yet meet the standard requirements by the law, then its time to transfer part of the vehicle weight to be taken up by the load.

This is a perfect way of making a cost-effective transportation means whose benefits will trickle down making a lot of other savings leading to a general cut on the cost of your transportation processes.

Contact us, get more specs now!!

The economic feasibility of the tanker is not just with it increased capacity to take more load but as well on the less amount of energy that will be used by the tractor to tow it from one destination to the other.

Aluminum alloy tank trailer (Lightweight)

1. Why You Need Light Weight Model?

The question of the need to have a lightweight model of a tank trailer for the transportation of oil has sparked a lot of interest among transporters.

However, their reasons for that are fully justified owing to the regulations applied in the industry. A lot of factors come into play and therefore, users of these transportation means should be conversant with the reasons why this is important.

It is not only for personal benefits but for the realization of a mandatory statutory requirement. Here are some of the reasons to take this route:

- Lighter trailers can carry more oil/fuel. With a lightweight tank trailer, it means you can take in more weight than a normal oil tanker can take. The weight is reduced from the tanker can be replaced by the load in a way that does not breach the set regulations on the amount of weight that can be carried by transport vessels and vehicles.

- Improve efficiency and reduce fuel consumption of truck tractor. Heavy tank trailer constructions take in a lot of fuel energy to pull hence making them infective in terms of affecting the ultimate cost of the oil in transit. On the contrary, lightweight operations consume less fuel. Therefore, savings are made on truck tractor fuel compared to heavyweight tank trailer operations.

- Parts made from aluminium and aluminium alloys are more valuable for reuse compared to those of steel construction. Actually, the value of aluminium alloy tankers recovered can reach 30% of the cost of tankers. This virtually eliminates vehicle operating costs.

- Minimized cost of building tank trailers. Less material is used in the construction of lightweight tank trailers. The cut-out material parts can be recycled and re-used for other projects where deemed useful.

Contact us, get more specs now!!

2. How to make the lightweight model?

Different authorities have heavy-duty vehicle programs that should be adhered to particularly on performance-based standards that have to do with the general construction if the vehicles used in transportation.

Improvements in vehicle manufacturing and building are based on the need to make them fuel efficient and one of the ways to achieve that is by making sure that they are light in weight.

As a result, the promotion of lightweight vehicle developments is much needed particularly in the transportation and logistics industry where the consumption of energy fuels is very high along with other basic requirements.

Other improvements in this sector include the use of low rolling resistance tires and the use of lightweight materials to for the tanker trailers.

In areas where the tank trailers cube out, lightweight materials use makes the entire vehicle lighter than it would be if it was entirely made of steel.

In that case, the final vehicle made would need less energy to accelerate and overcome the rolling resistance forces.

Materials such as aluminium alloys lead to lightweight constructions that significantly help in offsetting the extra mass that comes with heavy constructions.

Aluminium alloy tankers (inner)

While not all parts would perfectly be made of this lightweight material, a good number of them can.

Heavy vehicle manufacturers have the task of identifying all the structural and vehicle body components that can be made of lightweight materials.

Most important to note is the research that has driven a lot of developments most of which are specified in different regulations and requirements of heavy trailer constructions.

All these regulations come up with proposals of the lightweight materials that can be applied pegged on a number of other factors as a means of compliance to the said standards.

Read more: The Key Specs Affects How Many Liters a Fuel Tanker Hold

Contact us, get more specs now!!

The manufacturing of a lightweight tank trailer model depends on a number of factors.

The main ones are the type of material used in the fabrication of such tankers, the design of the tank trailer and minimizing the material used for some parts too. Here are full details on these options used to make lightweight tank trailers:

2.1 Material

The choice of material used in the construction of a tank trailer can either make it heavy or light. The commonly used materials used in the construction of tank trailers are steel and aluminium.

Steel constructions are usually heavy hence not suitable for lightweight tanker manufacturing. Here are key reasons why various types of steels are not applicable in this lightweight technology, particularly stainless steel and carbon steel:

- Carbon steel needs painting and galvanizing in the surface to prevent erosion by rust and this further adds to the weight of the tanker.

- Generally, steels have a higher density than aluminium alloys hence not suitable for making lighter vehicles

The materials used in the construction of a lightweight oil tank trailer model are Aluminum alloy, Magnesium alloy and High-tensile steel. These can be used to reduce the weight of your tank trailer effectively.

Read More: Aluminum and Aluminum Alloys

2.2 Working with Aluminum Alloys

Here are some of the main advantages that come with manufacturing oil tank trailers using aluminium alloy and the other materials used for lightweight construction:

- Owing to the lightweight factor, the aluminium tank trailer has room for taking a higher load capacity than the conventional steel tanker constructions. This adds significant cost savings to your oil transportation operations.

- The materials are lighter than steel hence the total volumetric weight significantly reduces the final weight for each of the oil tanker trailers.

- Aluminium tanker constructions are more safe and secure to use in this industry

- Still, aluminium is resistant to corrosion through rust hence does not pose any danger of pollution to the oil while on transit. Therefore, you can rest assured that your product will arrive at your destination safe and secure. There are no fears of losses due to rust and corrosion impurities.

The type of material used for oil tanker trailer construction is key in determining its loading capacity and the total cost. These factors can be blended together to produce the most desirable construction for a given application.

For lightweight constructions, one of the objectives is to ensure that there is more room to take much cargo and still stay within the weight limit requirements.

An aluminium tanker and a steel tanker of the same size will have different capabilities when it comes to the amount of oil to transport. The aluminium tanker will definitely take more.

Aluminium alloy shell

By comparison, aluminium is lighter than steel and generally of a lower strength than steel as well. However, this is not to imply that aluminium tank trailers are weak.

On the contrary, they have sufficient loading capacity to move oil and other fuels in bulk from one point to another. The initial costs involved in the construction of aluminium tanker trailers may be higher than that of a steel construction.

However, its subsequent use and application guarantee cost-effective operations where an aluminium tanker would take lesser trips than a steel tanker if they were all needed to transport the same amount of oil or fuel from one destination to another.

Raw materials are sourced from reliable suppliers of high-quality aluminium materials to be sure of the grade of materials to be used in the tank trailer construction.

Basically, all materials are sourced from the best dealers in the market and that leaves zero chance of having poor quality tank trailers.

The need for affordable and efficient tank trailers has sparked a lot of interests from various dealers in the industry. Therefore, known brands have been in the forefront delivering high-quality materials for use in this application.

Read More: Fuel Tank Trailer Guide – Oil Tanker Trailers Designs & Specs

Contact us, get more specs now!!

2.3 Design

Prior to the actual construction, design engineers simulate the weight of what needs to be made to ensure that it is within the most effective desired range in terms of weight and usability.

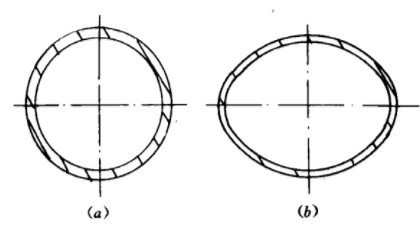

Taking into account other factors, tank trailers have varying shapes and configurations: ellipse, circle and rectangular shapes. The height to gravity ration is usually designed around 1:0.79:0.65.

A big fuel tanker is usually designed with an ellipse shape and around the rectangular shape, that enhances its stability for high weight capacity loading.

The lower center of gravity applied in this kind of shape is useful in creating balance and stability in this kind of trailer.

However, for the high-pressure tanks, they are built with a circular configuration. Ideally, the design works take different forms as highlighted below:

1. Shape of Tanker

The round or oval tanker reduces the concentrated stress when the liquid fluctuates inside the tank. So, the round or oval tanker can have a thinner thickness than the Rounded Rectangle shape.

In that case, it significantly reduces the overall weight of the tanker. With oval and circular shapes, there is no concentrated loading and this becomes a very useful factor of safety in the construction.

Most importantly, it also helps in reducing the amount of material needed to take up the pressure of the liquid if it were another shape such as a rectangular one.

Round or Oval tanker

Due to the corners in a rounded-rectangular shape, further reinforcement is required or a thicker construction is applied to take care of stress concentration around the corners.

This ultimately increases the weight of the tanker generally. However, the oval and circular shapes will not require a thick wall because the pressure is evenly distributed all around it.

Contact us, get more specs now!!

In the end, there will not much of material used for its construction. If the material used for the design is aluminium, then the weight is significantly reduced further to levels that can allow the taking of more cargo.

Rounded Rectangle

2. Increase and Reinforce Circle’s Quantity and Size

Another factor applied in design is playing around with the size of the tanker while maintaining the standard weight requirements.

Based on the material that will finally be used for the construction, the tanker could be either small in size or length.

While maintaining the total general weight, a designer can iterate the values for a lightweight construction using such materials as aluminium and end up with a larger circle-shape tanker or one that is big lengthwise or both.

Despite having the same total weight with a steel tanker of the same shape, the aluminium tanker in this design takes in more weight than the steel option. The end result is as shown in the elongated light-weight designs above and below.

Light-Weight Tanker Designs

To be sure of what you are going to get in the market, ask for the mechanical designs of the tanker that you are considering to purchase.

This is a basic request that all buyers need to make before buying in the tanker. Look for all the design details to establish the details of the material gauge used for the tanker construction.

This way, you will be sure of what you are buying before you make the final payment for its delivery. Ensure that the drawings match the kind of trailer that you are looking for in your application.

2.4 Reduce Weight of Other Parts

1. Pedestal chassis- punching and reduce weight

Conventional tanker trailers are made of long continuous steel beams that are usually very heavy. Although they are needed for structural support to the trailer and the cargo on board, they at times are too strong for the application.

They add extra weight to the trailer construction and therefore, it may be of no value addition to the tanker trailer. In oil tanker trailer designs, modifications can be made to reduce the total weight of the trailer.

This is usually done carefully without compromising the strength of the construction for each of the sections that have been modified in the building process.

Punched Pedestal Chassis

For instance, the Pedestal chassis can be punched to reduce the material on it. This is specially done where the shapes punched out are either circular or oval in shape as shown above.

Circular and oval shapes help in reducing stress points that could otherwise result in the punching of either rectangular or triangular shapes.

The latter introduces stress points that can significantly affect the strength of the chassis which is the main load-bearing framework.

For that matter, a desire to have decreased weight and lightweight construction are usually made in consideration to the strength needed for support.

Therefore, your lightweight construction will not have a compromise on the overall strength in totality.

Contact us, get more specs now!!

These modifications are not made haphazardly. There is a systematic way of making these reductions and therefore, it is important to make sure that you don’t compromise the strength of the chassis.

All these checks must be done with the help of the design engineer preferably with the use of technical diagrams used in the building process.

When done perfectly, punched tanker trailer members add great value to the general construction. Ideally, the desire for lightweight trailer construction should not override the need for safe and secure oil tanker transportation systems.

2. Double Tires to Single Tire

In oil tanker trailer lightweight constructions, there is a detailed assessment of the entire trailer structure to ensure the removal of any unnecessary weight usually added on conventional tank trailers.

Again, this is also done without compromising on the desired strength and quality of the final product.

Initial trailers were over-designed to take care of safety factors but with improved technologies nowadays, manufacturers can comfortably take care of making some modifications without endangering the cargo to be loaded on such tanker trailers.

Tank trailer with double tires

Part of the things that can be done is the replacement of double tires with single tires. Additional weight that comes with double tires may not be necessary for some applications.

Therefore, the building and assembly of these types of lightweight tank trailers also take into consideration such factors.

With proper empty weight and load calculations, the double set of tires can comfortably be replaced with single tires without affecting the safety nature of the trailer.

There exist better systems of ensuring balance and stability in tanker trailers these days hence no need to put in multiple parts to realize this need.

Competent tank trailer manufacturers know how to much weight with the best tires that can do your job conveniently and efficiently. They will make the best choice of tires to help you meet your needs without any risks whatsoever.

Tank trailer with single Tire

Over and above the extra weight, double tires tend to have a high rolling resistance hence increasing the consumption rate of the trailer tractor.

Ideally, the tanker trailer tires should move freely without any or with minimal resistance. To achieve this, single tires can be used especially those with a low rolling resistance.

It will go a long way in enhancing the quality of operations as far as cutting costs is concerned.

Buyers are therefore advised to check the quality of tires used for lightweight technology and make sure that they meet recommended standards.

Don’t just be happy because your tanker trailer has single tires. It is your responsibility to check the brand and ensure that is from a renowned company.

Make sure that you understand your obligations in relation to the nature and type of construction and assembly done on your tanker trailer. Despite the desire to have lesser weight, no standards should be compromised because of that.

Contact us, get more specs now!!

2.5 Important Remarks

In your search for the best lightweight tanker trailers, study the market carefully to take note of reputable companies with the most advanced lightweight technology.

There are companies with a good track record in the industry packed with a team of dedicated professionals who will guide you through a process of identifying the options there is in the market.

Remember to ascertain the types of materials used in the construction. They are the basic requirement to consider when searching for lightweight tanker trailers for oil transportation.

Your focus should be on trailers made from aluminium alloys or high-tensile steel. Carbon steel and stainless steel may not be the best materials to meet this kind of need.

The design for the oil tanker also counts a lot in determining the weight of the vehicle. It is highly recommended that you check with your supplier to get the technical drawings of the same.

The details contained in such sheets should help you understand the kind of tanker you are buying.

Compare the wall thickness of conventional tankers with that of the lightweight tanker and see whether it will give you the kind of weight measures you are looking for.

The ultimate goal of this process is to ensure that your tanker can take as much oil as possible to cut down on the number of trips you will make in the transportation of the product.

Inspect your oil tanker trailer thoroughly before leaving the premises. Check where reductions have been made to make sure that they have been done professionally.

Most importantly, check the chassis to make sure that the shape of the punches made on it are oval or circular in shape.

Read More: 4 Trends in Liquid Tank Trailers

3. Conclusion

Tank trailer construction technology has continued to evolve over the years. Ideally, the heavy cargo transportation industry has had major developments since the inception and use of heavy tank trailers in the transit of heavy cargo.

However, this has never been without regulations from the governing authorities, both local and international. Measures have been put in place to take care of the existing road framework as built by government institutions.

In the efforts to comply with such requirements, tank trailer manufacturers had to come up with solutions that would not affect the efficiency in the transportation industry.

With checks and controls by the authorities, tank trailers would be limited on the amount of cargo that they would take in a single trip.

Contact us, get more specs now!!

However, amicable solutions have been found through the choice of lightweight construction materials, optimized designs and the direct reduction of material on some of the trailer parts.

Conventional steel tanker trailers for oil transportation are now being replaced with aluminium and other lightweight material constructions.

Even though aluminium may prove difficult to work with and expensive initially, a lot of savings are made through its subsequent use.

This is due to the fact that lightweight constructions can take up more cargo without breaching the set rules and regulations in the industry.

Ideally, the total accumulated benefits over the years while in use presents cost-effective operations that could otherwise not have been realized through the initially cheap-to-make steel tankers.

Optimized designs have also played a major role in the realization of lightweight constructions. The replacement of rectangular shape tankers with oval and circular shape tankers has largely impacted on the wall thickness needed for tankers.

Oval and circular shapes can comfortably take high pressure and therefore, the wall thickness is greatly reduced. That means that the total weight of the tanker is far much less than that of conventional rectangular shapes.

This is a great milestone towards the achievement of higher objectives in the transportation and logistics industry.

The reduction of material used for construction can also be realized by punching round and oval shapes on some of the tank trailer parts such as the pedestal chassis.

This is carefully done without compromising on the quality and strength of the tanker trailer.

The benefits of the oil tanker trailer are many by far. A lot has gone in to ensure that there is a possibility of maximizing the amount of oil that can be transported in a single trip to minimize the cost of transporting the product in general.

Therefore, lightweight oil tank trailers end up being of great use in this sense.