The hydraulic platform transporters also known as the shipyard transporter (SHT) is a self-propelled hydraulic transporter that comes with capabilities of multi-mode steering, synchronous lifting of the entire vehicle, hydraulic lifting and driving.

On the other hand, the Self-Propelled Modular Transport (SPMT) is a vehicle with similar abilities of hydraulic steering, hydraulic lifting and hydraulic driving.

It is used for the transportation of heavy cargo that can go as high as over 100 tons. This special type of vehicle is commonly used for the transport of oversize goods that cannot be transported through other means.

One. Project Cargo Transportation

A project cargo involves the global transportation of heavy and high-value parts and equipment specifically meant for certain projects.

It involves heavy lift procedures and deals with shipments of various components that need disassembly to facilitate consignment and reassembly after arriving at the destination.

This takes into account details of the nature of the load under transportation. This is more especially in the construction industry, the shipyard industry, chemical and wind energy sectors among other fields.

Read More:

What is Heavy Lift / Project Cargo Transportation?

Essentially, there are a lot of complexities involved in handling these high-value equipment and project parts that can’t afford to be damaged.

For that reason, a special type of transporter is needed to carefully and safely handle this type of cargo.

So, which of the SHT and the SPMT can comfortably be used for the transportation of project cargo? Find out in the details below:

Two. Notable Differences between SHTs and SPMTs

There are notable differences between the SHT and SPMT in a number of ways.

Each one of them has special capabilities in handling different kinds of loads. The distinguished features and capabilities for each of these transporters are discussed as below:

- Size and Dimension

Project cargo is usually massive and heavy hence the need to look into the dimensions and size of the vehicle being used for transportation.

Based on the type and size of cargo you got, you can now determine what type of transporter to choose. The yard transporter has a larger platform usually by 1 set with a length that can be up to 30m.

It has commonly been used in the shipyard to move ship parts to designated areas for assembly.

Read More:

Shipyard Transporter Ultimate Guide – Learn the Technical Specs

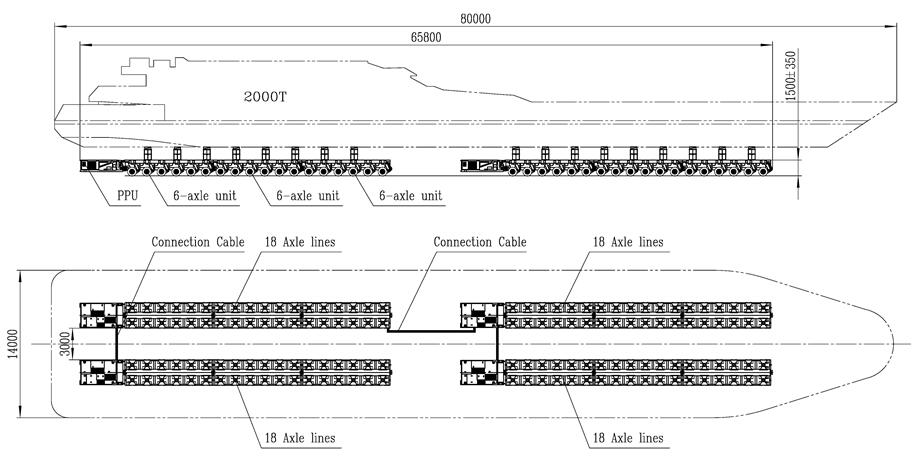

On the other hand, the SPMT requires some form of combination in order to attain a large working platform.

Again, the SPMT is much costlier than the yard transporter. With the possibility of combining the SPMT to increase its loading capacity, it can be used to carry oversize cargo through segmented transporters.

Such loads as can be carried by the SPMT include large blades for wind turbines, dozens of tanks and so on.

- Load capacity

Every transporter is designed to take a feasible size of cargo that ensures that the operations are highly valuable and economical.

The hydraulic platform transporter on its part is a lighter capacity model compared to the SPMT. Therefore, it can only be used for lighter weight cargo applications taking up loads beginning from the weight of 35tons.

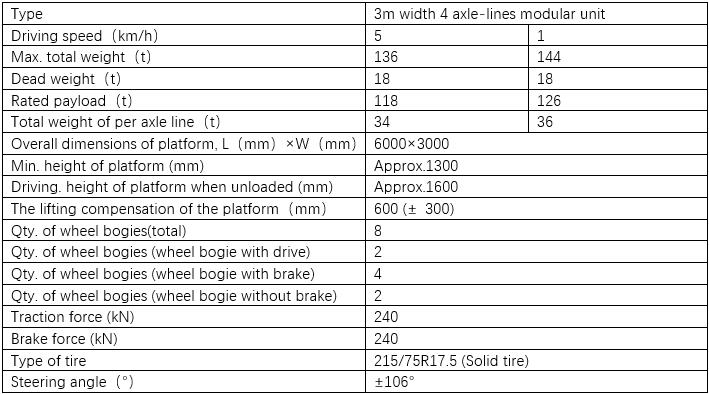

The SPMT’s 4-axle lines model has a min capacity of 144tons. However, it is superfluous sometimes.

It is important to note that the SPMT has two models of 2.43m and 3m respectively each having different loading capacities.

The 3m SPMT has a maximum load rating of 36 tons per axle whereas the 2.43m model has a load capacity rating of between 40 and 48 tons for each axle.

Typically, the loading capacity for the 2.43 SPMT is higher than that of the 3m SPMT. For that reason, the 2.43m SPMT is more expensive than the latter owing to its capabilities.

Read More:

What is SPMT? Learn Basics of Self-Propelled Modular Transporters

- Conditions of Use

The SHT is a special-purpose vehicle with hydraulic self-lifting and self-propelled functions that aid it during operations. It is suitable for transporting heavy loads in the shipyard industry.

Ideally, its use is mainly for short-distance transportation or material handling on-site.

The SPMT can be used on-road project, specifically for short midway transportation. This type of transporter has found major use and application on a number of industries owing to its ability to take a wide range of products.

They have sufficient capacity and room to take such bulky and heavy loads.

Heavy cargo logistics are very complex and weighty to manage and that is why only some companies specialize in doing so. It is a special transportation operation that requires special transporters like the SPMT.

It can take cargo in the form of equipment and machinery to stacks of raw materials and manufactured products.

Most importantly, customization can be done to transport any size and weight of cargo within its capabilities with the proper packaging.

Other industries that have heavy cargo that needs special transporters include the electric power construction industry, chemical industry construction industry and project cargo among others.

Project cargo, in particular, is a lot demanding during its transportation and that is why such transporters as the SPMTs have been very useful in transporting them.

Such cargo includes construction blocks usually made of concrete that is normally heavy and not possible to handle them with other types of transporters.

Other types of products include road sections and concrete bridge sections. With a transporter of this magnitude, project cargo transportation becomes a huge possibility.

- Combination Capabilities

Heavy cargo transporters come with a possibility of combining a number of them to create space and capacity for taking much bigger cargo.

For example, the SPMT has more combinations for different and complex demands of heavy cargo transportation.

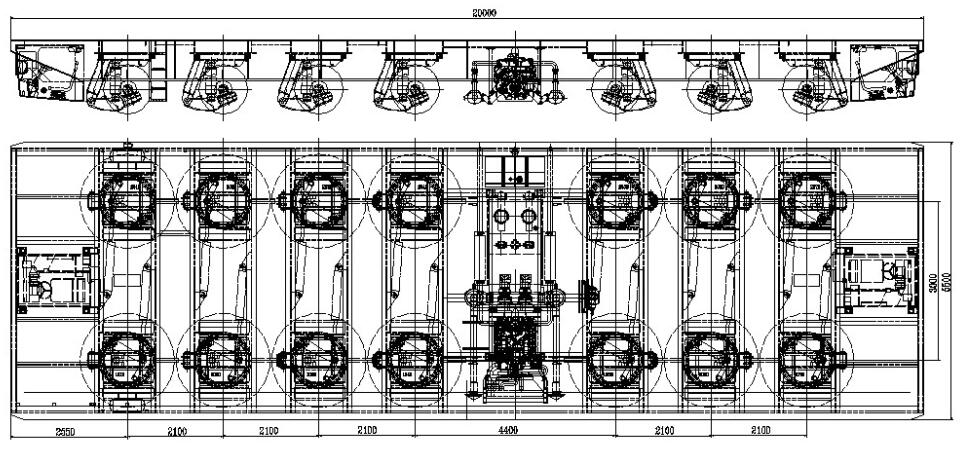

For the self-propelled modular transporter, the frame is the main load-bearing component.

The cargo boarded on this transporter is dangerous and that is why there is a safety factor included in the design of the transporter frame in relation to the load capacity rating.

The main load-bearing sections of the SPMT are the wheel bogie, the frame’s main girder and several others.

The design adopts a robust box-type beam structure with a high-performance welding plate with a yield strength to the tune of 690MPa.

The entire frame has a great stability and strength to withstand bending moments due to concentrated loading efficiency.

The middle longitudinal beam section of the frame has a trapezoidal box framework and oscillating cylinder cases welded together with the frame.

There are 3-chips-shape pin holes at the centre of both ends of the frame to facilitate an end-by-end coupling.

The frame has bolt holes to the side to make room for side-by-side coupling. There are four hook point close to the four corners of the transporter frame bearing the dead weight of the unit for hoisting.

Hydraulic coupling pins are used between the modular unit and the power pack unit. The connection between two modular units can also be made in an end-by-end combination.

The high combination efficiency for the SPMT is due to the hydraulic pipe used to enhance fast coupling and the electrical connectors for the electrical cable.

SHT is commonly used in either 1 or 2 sets. Its combination is simpler than that of the SPMT. Ideally, the shipyard transporter can be combined together either in an end-by-end connection or a side-by-side connection.

In these combination modes, one can realize a number of steering modes like the all-wheel steering along, diagonal steering along mode, circle steering mode, front-wheel steering and so on.

Even with these connections, operations can be conducted from any cab unit. Again, the communication happening between the transporters is realized through the coupling cables making the operations a lot more convenient and easy.

Conclusion

The transportation of project cargo requires robust equipment and machinery to enhance safety operations owing to the massive loads and weight involved.

The Shipyard Transporter and the Self-Propelled Modular Transporter provide options to take up these types of cargo.

However, the choice of a given transporter will rely on the distance of movement to be covered and the amount of load to take.

Shipyard transporters move loads within shipyard and again, are best suited to move loads beginning from 35 tons such as ship sections and parts.

The SPMT on its part comes in different models giving options to the user to settle for either based on the size of cargo to be taken.

Looking at these specifications and characteristics, the SPMT would definitely do a much better and extensive job handling project cargo.