The choice of a cement tanker trailer is normally pegged upon a number of factors. Dealers in cement tankers have identified a number of needs in the transportation of bulk cement and have come up with various versions of this type of vehicle.

Therefore, it is prudent for every bulk cement tanker buyer to consider all the options before settling on any one of them. For instance, there are designs made to support heavy loading and offloading.

This type is made with high stability. You need to know why you are choosing one bulk cement tanker over another in order to make the most suitable option for your budget.

Here is useful information that will help you in the choice of a good quality tanker for transport bulk cement:

More details about the cement trailer:

What is a bulk cement / powder pneumatic tank trailer?

Pneumatic Powder / Cement Trailer Operation – How to Unload Cement Tank Trailer

1. Know the capacity you want to transport. Choose the right Specifications

This would probably come first in your considerations. How much of cement do you want to transport and for what distance.

If you have a lot of stock to transport, it is important you get a tanker with a high volume capacity and strong enough to manage that weight.

Getting the most appropriate option for your cement capacity will come as a result of a combination of various specifications. You will not just be looking for the volume needs only.

It is important to establish whether the volume provided is fully supported by the construction approach. The durability of the tanker is also something you need to look at.

Material of Construction: You can choose between stainless steel and aluminum alloy constructions. With a stainless steel construction, your cement tanker will not be easily attacked by rust hence can guarantee long-life.

A bulk cement tanker of aluminum alloy has advantages of being light and a more economical option to go for. However, aluminum alloy cement tankers are a bit costlier than those of a stainless steel construction.

Aluminum requires special manufacturing processes and welding procedures that increase the cost of making it.

Tanker Thickness: The thickness of the tank is an important aspect to check. It is normally chosen according to the tank’s capacity.

There are standards already set in the industry to guide you in making the right choice. Therefore, don’t think that the one with a thicker wall is the best. It must well-matched with its capacity requirements.

- Important Consideration

Common specs for reference: These are specifications that will help you to clearly understand what you need to match your current needs.

Get Detailed Specifications!

You should gain access to every kind of information that you need before making your final option. Ask for any type of details that you would need to make a choice of the bulk cement tanker that you will need.

Get answers to your questions on the capacity that you want to transport before buying your tanker.

2. Design of tank trailer

With the design of a cement tank trailer, there are two important parameters to look out for: volume effective rate and the residual ration. Here is detailed information about the meaning of each of these two aspects:

Volume Effective Rate: The Volume effective rate of your bulk cement tanker should be high enough to cater for your needs. Ideally, this refers to the maximum volume of your cargo that the tanker can carry.

Definitely, the cement tank cannot be filled to capacity but it should be able to carry a good volume of cement that matches its capacity.

Residual ratio: A good bulk cement tanker should have a low residual ratio. Typically, the common one is 0.3%. Today, you can get a residual ration between 0.05% and 0.3%.

This is a very important parameter to check. With a low residual ration, the cleaning of your cement tanker becomes a lot easier. Most importantly, it prevents your cement from contamination.

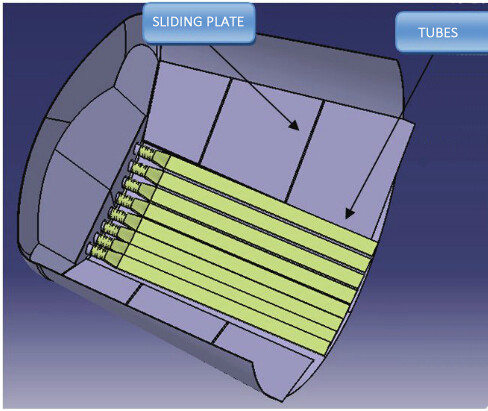

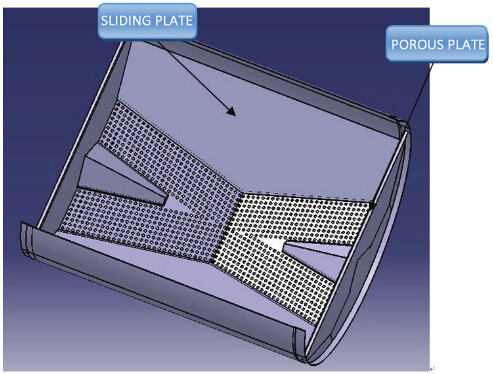

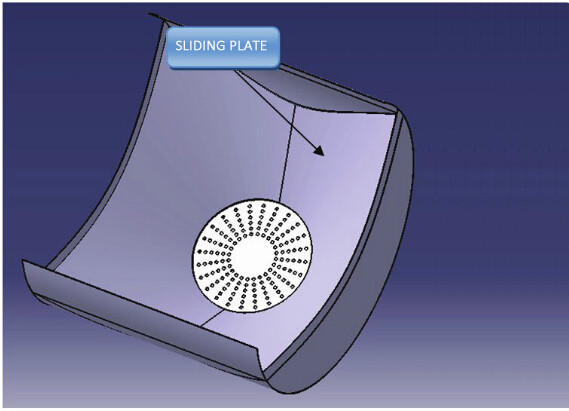

Different types of Fluidized bed:

tubes fluidized bed

x type fluidized bed

funnel fluidized bed

These two aspects should carefully be studied and this where you need all the information as it pertains to the construction of your choice tanker.

You have the right to ask for mechanical drawings and documentations to establish the design and whether it meets these criteria.

You can engage a professional to help you study this. Remember any decision you make at this level will have a lot of impact in your operations.

Therefore, don’t rush the process. Do what you can possibly do to be fully acquainted with your product before you buy it.

Get Detailed Specifications!

3. Quality of tank Production and Welding

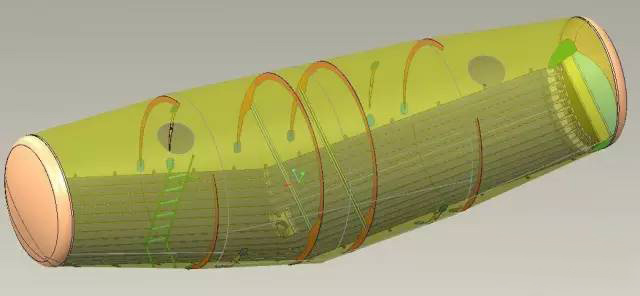

One thing that you must understand with a pneumatic powder tanker commonly used for the transportation of bulk cement is that it is high pressure vessel.

For that reason, you must ensure that the tank is tough and solid enough to enhance the quality and safety of your operations.

This is a big investment you are making and therefore, you need to be sure that your money is not going into a pit. You don’t want to keep going for repairs quite often.

This can be risky especially when you don’t get the right person to do it. Again, it is a costly affair.

pneumatic tank trailers structure

Basically, production and welding determines whether the tank is solid.

More than just checking at the mechanical designs and drawings, it is important to ensure that there is good workmanship on the vehicle.

Check whether there is an adequate testing procedure and accountability system for the tank trailers. Keep off manufacturers that don’t do production tests on their vehicles.

Where possible, ensure you get certification proof of the same.

Even if the company is well-known with famous and quality suppliers of the raw materials, the final product made is subject to scrutiny by the prospective buyer.

There are a number of small steel mills whose raw materials don’t meet the set industry standards.

For that matter a lot of caution should be exercised when making the final choice of what bulk cement tanker to buy.

You don’t have to be an expert at establishing this but the little guidance and help from a knowledgeable person in the industry should help you make a good choice.

Get Detailed Specifications!

4. Bulk Cement Trailer Options to Buy

In your search for a bulk cement tanker, you will come across 3 structures to choose from. There is a reason why these three exists and therefore, it is important to understand that so that you can make the best choice for your application.

Of these three are the funnel, lifting and horizontal structures. Each of these tankers is designed for a particular type of cargo and weight. Here are detailed descriptions of why you should choose one structure over the other:

- Horizontal Bulk Cement Tanker

In the market, the horizontal structure type offers great stability due to its low center of gravity. If you are looking for stable operations, this is the bulk cement tanker to go for.

More than that, it will give you a bigger capacity compared to other structures in the market. However, this type has only one compartment.

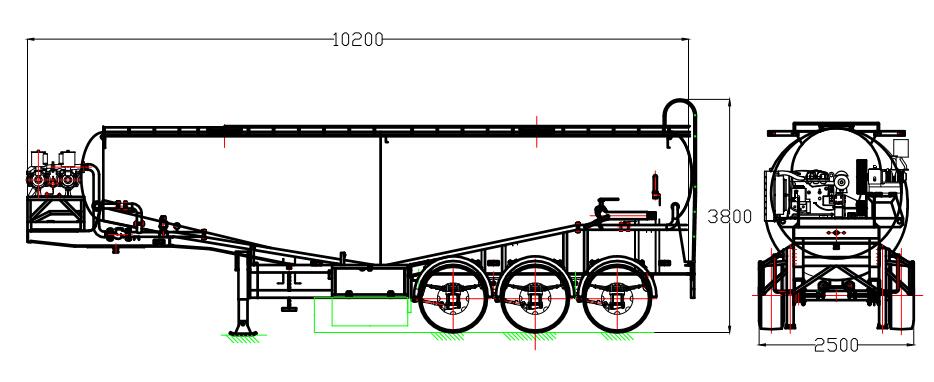

horizontal cement trailer drawing

This means that you will require less time to build the gas pressure. Again, discharging the gas will also take less time. Generally, this tanker is user-friendly and you will find an easy time operating it.

Should this be the choice you intent to buy, here are some of the important things to note: this type of tanker will only accept a pneumatic discharge.

The process of discharge is also inefficient since it does not discharge all your cargo from the tank. A portion of it will be trapped inside.

As a result of this, you will not find many materials being transported by this type of tanker. All you may successfully transport will be cement or fly ash – nothing more.

- Funnel Bulk Cement Tanker

With this type of tanker, you will be able to transport a wider range of products than the horizontal type. If you are looking forward to use your cement tanker for a number of materials, consider buying the funnel type.

You will be able to ship granule and powder materials or the massive ones. The pneumatic discharge in this setup can be used for both granule and powdered materials.

The massive materials will be discharged directly into a predetermined pit through tipping gravity. Powder carried in this type of tanker can easily slide to its base of the fluidized bed.

This is made possible by angle between the horizontal plane and the cone bus bar hat is usually bigger than or equal to 45°. Another important aspect to note is that, the fluidized bed section is not big.

That means that the residual rate in your operations will be very low.

The design and material choice for the tank is made to reduce the residual material following a discharge. This is something to consider in your choice of tanker.

The material is also of a type that won’t get polluted or deteriorated along the shipment process.

The funnel type of a cement tank trailer is your best choice if you still want to use it in the transportation of food items like flour and powdered chemical material.

- Lifting Bulk Cement Tanker

If you have different operation needs, this is the type of cement tanker to consider buying. You will get a lot of benefits with the lifting bulk cement trailer than with the funnel type and horizontal type structures.

Ideally, this lifting bulk cement tanker is a single storehouse construction. Once the tanker is lifted, its big angle of tilt makes the offloading operation easy.

Again, the discharge speed of this type of structure is comparatively faster than that of both the funnel and horizontal types.

lifting powder tank trailer

With the lifting cement tanker, you will be able to carry various cargo materials. The ranges of materials that can be transported through this tanker are granule material, powder such as cement and block material as well.

There are two ways of discharging your cargo from this type of tanker:

by gravity tipping or through pneumatic discharge. The fluidized bed is small and this implies that there is nothing much left as residual after discharge. Ideally, the residuals are very tiny.

You should also know that the internal structure of the lifting bulk cement tanker is overly simple. This translates to easy disassembling and cleaning of the fluidized bed and most importantly in a convenient and fast way.

Most people buy this because they can change from one type of load to a different one. This means that it can be used for a number of purposes.

Conclusion

The bulk cement tanker is very useful hence the reason why you should be knowledgeable about it, its operations and the options that you got in the market.

You need this type of tanker on large building sites, warehouses and cement factories. In terms of operation, this tanker utilizes compressed air to help in discharging cement from the tanker.

As discussed in here, the most differentiating aspects of bulk cement tankers include the shape in which the tanker has been formed, the type of cargo you want your tanker to carry and generally, the size of the tanker you need.

As you plan to out to buy, it is important to know the set rules and regulations regarding the use of this type of tanker in your country.

Some of the models are purely designed to match the regulations by the country on the transportation of powdered cargo such as cement. For that matter, the structure of trailers tends to be different across countries around the world.

Despite these requirements, the functionality of all of these cement trailers is usually the same irrespective of the manufacturer.

In your choice of what bulk cement tanker to buy, make sure you check for the materials that were used in the building of the tank trailers.

Learn more on how to inspect various tank trailers components and also the manufacturing process used in the building of the tanks.

Ask yourself what you should be focused on and how you will make sure to stay safe as your drive the tank trailer before buying any.

It is also important to get to know what aspects to maintain in your tank trailer and the components that should be looked at when doing maintenance.