You can tell from the name that the tank trailer is used to transport powder cargo. However, the trailer carries powder cargo in bulk.

The main applications of this tank trailer include transporting cement, flour, lime powder, mineral powder, fly ash, chemical powders, and stone powder.

This type of trailer is widely used on large construction sites and cement factories and warehouses. The tank trailer uses compressed air to discharge powder from the tank.

Ideally, the cement tank trailer you need falls in this category. There is a reason why this type of a trailer is used. By characteristics, these are pneumatic tankers that are usually vacuum-sealed and enclosed used for the transportation of cement among other powders both in the construction and food industries among others. They provide the owner with the following benefits over conventional trailer types used for the transportation of powder.

- They are easy to work with. Offloading the tank is made possible due to the installed pneumatic system and saving time in between transportation trips.

- The cargo is carried in a vacuum-sealed tank. This prevents the entry of air that may tamper with the quality and usefulness of the product. Ideally, the tank is made in such a way that no mould, germs or moisture can get inside and contaminate it.

Here are the different kinds of tank trailers guide:

- Fuel Tank Trailer Guide – Diesel, Petrol, Oil Tanker Trailers Designs & Specs

- LNG & LPG tank trailer guide – Learn Tankers Specs & Design

- CNG Tank Trailer Guide – What is CNG Tanker?

- Asphalt / Bitumen Tank Trailer Ultimate Guide (Insulated Tank with Heating Device)

- Pneumatic Powder / Cement Trailer Operation – How to Unload Cement Tank Trailer

Contact us, get more specs now!!

1. Different Structures of a Bulk Powder Tank Trailer

Bulk powder tank trailers come in three different structures that include the horizontal, funnel, and lifting structures. Each structure is ideal for a specific type and weight of powder cargo.

Let us now look at the advantages and disadvantages of the three types of structure.

For the pneumatic trailer tank to work effectively, several safety considerations have been put in place. Basically, pneumatic tankers tend to have certain safety issues that need the attention of well-trained and competent drivers. Here are the two main areas that have to do with the safety of this type of tank:

- Compressed air in the pneumatic system tends to move the cargo via pipes and compartments. For this reason, there should be accurate mechanical understanding and procedures of operation to ensure a smooth offloading process. The tank should also be kept in good condition through regular maintenance. Ideally, the only risks relate to the tanker itself and the cargo as a result of the breakages and blockages. Should there be air pressure leaks, injuries may result. Therefore, it is important to exercise caution at all times.

- Operating the contemporary pneumatic tankers can now be conducted at a ground level. This largely reduces the risks of falling. In the unlikely event that the driver will be forced to climb onto the tanker, there are handrails and ladders securely fixed to reduce any chances of injuries.

Based on orientation and structure, there are different types cement tank trailers as discussed below. Here are some of the many that you will find out there:-

- The Horizontal Type

The terrain on which you are conducting your operations can also dictate the type of tank to buy or rent. On a steep slope, you need a tank trailer with the greatest stability.

You may not have issues with space but could be the payload is quite heavy transported along a steep gradient. The stability with this kind of cement tank makes sure that you engage in safe operations both during loading, transportation and offloading.

There won’t be worries of spills or a tip-over. Still, with an increased stability, your insurance premiums will be kept low. This makes your operations very efficient financially and work-wise.

Horizontal Type Powder Tanker

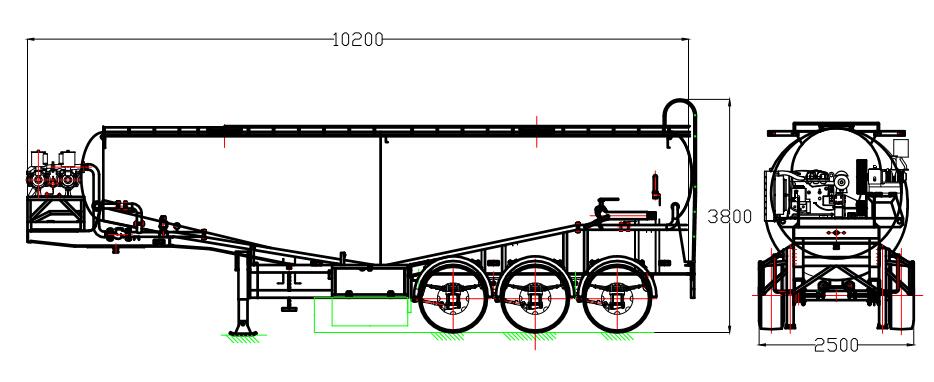

Below is a diagrammatic representation of the design drawings and nature of construction that has gone into the manufacture of this type of cement tank trailer.

It gives you a clear picture of what to expect and how your cargo will be supported and transported during your operations.

cement trailer drawing

Contact us, get more drawings now!!

Advantages: With this structure, the center of gravity of the tank is low, which enables its stability. The horizontal tank has a larger volume than other types of tanks. Most horizontal tanks have one compartment.

Hence, the time required to build gas pressure to the required level is short. The process of discharging the gas is also faster. Another advantage of a horizontal tank is that it is easier to operate.

Disadvantages: The horizontal tank can only adopt a pneumatic discharge. The discharge process is inefficient because it does not discharge all the powder in the tank. Part of it is left in the tan.

For this reason, the range of materials that can be transported using a horizontal is limited. The applications of this tank are limited to powder materials such as cement and fly ash.

- Funnel Type

pneumatic dry bulk trailer

Advantages: The design of this tank trailers allows it to transport a wider range of materials than a horizontal tank. The shipment can be either powder and granule material or the massive materials.

The pneumatic discharge can be used for powder and granule materials. The massive materials, on the other hand, are discharged into the designated pit by way of tipping gravity.

The angle between the cone bus bar and the horizontal plane is greater than or equal to 45°. Hence, this guarantees that the powder will slide to the bottom of the fluidized bed smooth.

The fluidized bed area in this type of tank trailer is not large. Consequently, the residual rate is very low.

The tank design and material reduce the left over material after discharge. The material also reduced the deterioration and pollution associated with powder shipment.

The funnel type of powder tank trailer is a good choice to transport food materials such as flour and powder chemical material.

- Lifting Type

This is probably the type of tank you will go for when you are offloading in a tight space. Get this type of cement tank if you don’t have so much space to carry out your operations.

Due to its function and manner of operation, this type is durable and at the same time has sufficient storage space. They are suited for different cargo with constructions of heavy steel or aluminum based on what you want to carry with it.

lifting powder tank trailer

Advantages: The lifting type has more advantages than the horizontal and funnel structures. The lifting type of a powder tank trailer can be described as a single storehouse structure.

When the tank is lifted, it has a large angle of tilt. Hence, the unloading operation is simple. The discharge speed of the lifting type is faster than the speed of the both horizontal and funnel types of tank.

Another advantage of the lifting tank type is that it can transport a wide range of materials. Examples of materials that this tank type carries include powder, granule material, and block material.

The lifting type can use both pneumatic discharge and gravity tipping. The fluidized bed is very small and this means that the residual materials are extremely little. The residuals are almost negligible.

An additional advantage of the lifting tank time is that the internal structure is simple. Hence, cleaning and disassembling the fluidized bed is fast and convenient.

You can change from one type of load to another when using this type of tank. Hence, it can be used for multi-purposes.

Go for this trailer offering you high versatility should you intent to transport more than just cement. There could be many other products that you want to haul and for that matter, you would definitely need to go for a versatile trailer.

For instance, you could be looking for a trailer for wet payloads, making it possible for you to offload without any worries, or concerning the space available for offloading.

Contact us, get more specs now!!

2. Different Structures of the Fluid Bed

There is a lot of engineering and design that goes into the construction of cement tank trailers. These pneumatic tankers are basically made of a single compartment used for loading cargo into them.

The construction is primarily of Aluminum or sometimes steel, providing capacities that range from 560-3120 cubic feet.

Where possible, you could get mechanical drawings of each of the tank trailer you consider buying in order to make an informed choice about the same.

It is highly recommended to understand the different designs available in the market and why you will be required to choose one trailer over another.

One of the major components of the bulk powder tank trailer is the fluid bed. The bed comes in different structures that include the X type, funnel type, and the pipe type. Each of these structures is described with illustrations below.

- X Type

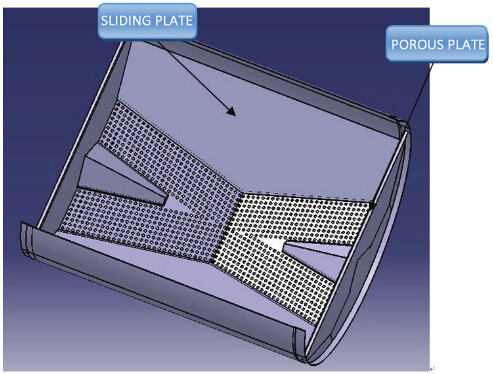

x type fluidized bed

The angle between the sliding plate and the horizontal plane is 42° to 45°. The fluidized bed has an X shaped at the bottom and hence the name of this type of structure.

The X type of the fluidized bed is longer and its discharging effectiveness is low. Hence, a large amount of residual materials remains after the discharge process.

Another disadvantage of the X type is that its operation is complex. The fluidized bed has a larger porous plate than other types, which makes its operation complicated.

- Funnel Type

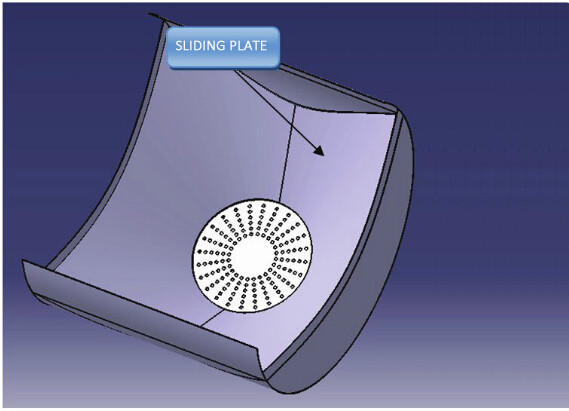

funnel fluidized bed

In this type of a fluidized bed, the internal sliding plate has a funnel shape, which explains its name. The angle between the sliding plate and the horizontal plane is 45°.

The fluidized bed at the bottom consists of a porous plate and a breathable fabric. The funnel fluidized bed is short and hence the tank has many compartments. Hence, it can transport different types of powder materials at the same time.

Disadvantages: The unloading speed of the funnel fluidized bed is slow. The speed is slower for materials with a large rest angle. The many compartments in this type of fluidized bed make its production process complex. In addition, the production efficiency is low.

- Pipe Type

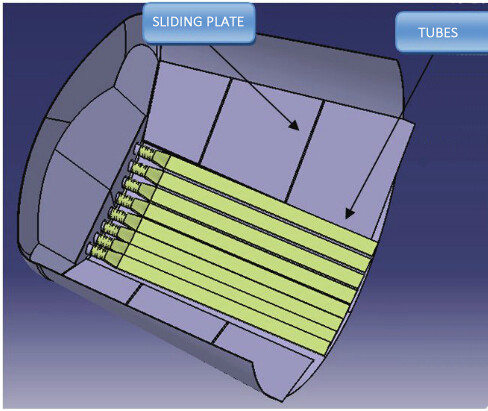

tubes fluidized bed

The pipe or tube type of a fluidized bed is joint to the bottom of the tank directly. Similar to the X type, the angle between the horizontal plane and the sliding plate is between 42° and 45°. The length of the fluidized bed can be up to 6 meters.

Hence, the compartments are fewer. Manufacturing this type of fluidized bed is easy and convenient. It has a simple structure and the unloading operation is convenient. Another advantage is that it is cost-effective and easy to maintain.

The main shortcoming of the pipe type of the fluidized bed is that the flow distance is long. Hence, trailers with this structure can only transport materials whose rest angle is small.

The materials should flow smoothly out of the tank. Examples of such materials include cement and fly ash.

Read More:

Tank trailer for transporting dry and liquid flowable materials

Contact us, get more specs now!!

Conclusion

There is a lot to consider in your choice of a cement tank. With the different structures of this type of trailer come different capabilities.

Each one of them has a different efficiency and application. Whether purchasing a new or an old tank or could be you are renting, this is an important guide to follow.

It is important to ensure what you finally settle on is the tank trailer best suited for the type of assignment before you. There are different cargo transportation needs and each of these tanks is designed around these needs.

In that case, you will definitely get a perfect choice for what you need.

Here is a perfect guide to making the right choice of a cement tank. You could be looking for a trailer that offers easy offloading or maybe help you offload in a tight space.

At this point, you definitely know what to go for. Should you have worries about hauling the cargo without any fears with the floors, belts, doors or any other thing that you could think of, engage a professional for guidance.

This guide helps you to save money, work efficiently and engage in the safest operations possible while moving your cargo.