This is typically an insulated tank trailer with a heating device used in the transportation of bitumen. There are different types of insulated tank trailers. This section focuses on the insulated tank trailers that come with a heating system. Some of the lessons you will in this chapter include:

- The definition and description of an insulated tank trailer

- The function of heating system in an insulated tank trailer

- Different types of heating systems in the tank trailers

- The trailer’s tank structure

Here are the different kinds of tank trailers guide:

- Fuel Tank Trailer Guide – Diesel, Petrol, Oil Tanker Trailers Designs & Specs

- LNG & LPG tank trailer guide – Learn Tankers Specs & Design

- What is a bulk cement / powder pneumatic tank trailer?

- CNG Tank Trailer Guide – What is CNG Tanker?

Contact us, get more specs now!!

1. What is insulated tank trailer?

This type of trailer is used to tranport special cargo such as sulfur, liquid phenol, and asphalt/bitumen. The tank trailer has a long heat preservation duration.

Users must install the heating tubes and heating system before using an insulated tank trailer for transportation. The heating system in the tank trailer uses three major types of heating modes.

asphalt tank trailer

The modes include the steam type, coal heating, and diesel burner type.

Molten asphalt and other related products are usually transported at high temperatures of up to 250°C in tanks that are independent and supported through specialized means.

The construction comes in different fashions. The tanks are normally well-insulated to preserve the heat inside.

To take care of the temperature differences and contraction/expansion linked with the transportation of these high-temperature materials, there is a special feature attached to it.

It helps in accommodating both the high differences in temperature and at the same time alleviate the loss of energy via the plating.

The tanks tend to expand in three different directions without causing any adverse effect on its structure and support systems.

For this to be achieved, the tanks are usually mounted on high-grade steel supports that are usually welded to the hull where several superimposed different rubber layers have been sealed.

The objective of having these rubber combinations is to help in absorbing the generated heat so that the maximum cargo temperature is cut down to an acceptable value, say of 80°C. the tank heating is usually done through a thermal oil system.

2. The Heating System

The heating tubes are usually installed outside the tank to avoid polluting the liquid in transit. The tubes may pollute the liquid if they are broken.

There are three major models of heaters that used in insulated tank trailers. The models include the diesel burner, electric, and coal burner models

Diesel Burner Type: The diesel burner model heats fast and has a high level of efficiency. It is expensive and has a high requirement for safety. However, the combustion of the diesel burner type is inadequate. It also produces waste gas.

diesel burner tanker

Coal Burner Type: The heater is safe and has a simple structure. It requires easy maintenance and hence it is cost effective. However, it is inefficient and inconvenient to use.

coal burner tank trailer

Electric heating type: This type of heating system is associated with high efficiency and no pollution. However, It’s a good choice, but equipment price is higher.

Contact us, get more specs now!!

3. Tanker Design and Manufacturing

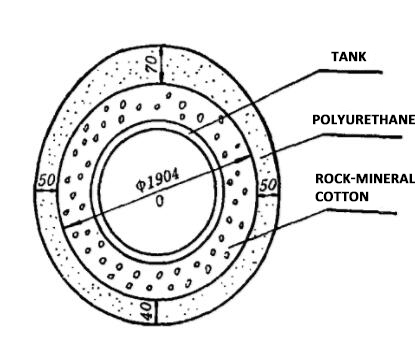

Steel is used to make the outer and inner layers of the insulated tank trailer. The insulating materials are used to make the interlayer. The insulating materials include rock-mineral cotton and polyurethane.

insulated tank

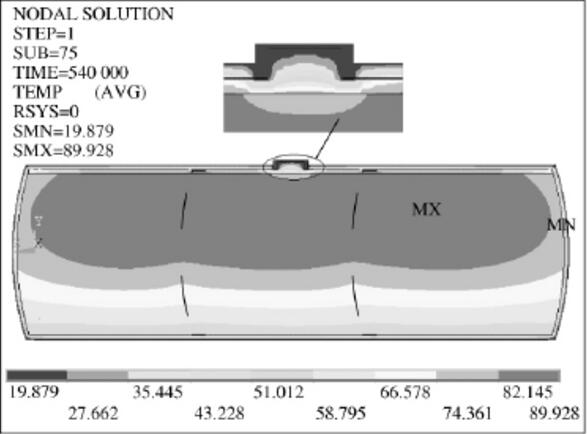

The heating pipe is placed at the bottom of the tank. Hence, the heat loss rate is different for the different parts of the trailer. The heat loss at the top of the tank is approximately 30% higher than the rate in other parts.

thermal distribution of tank

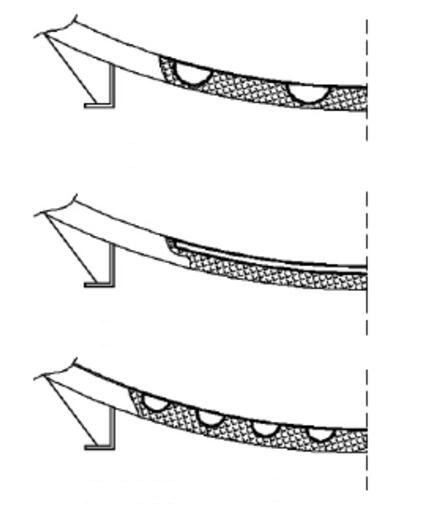

different structures of the heating tube

For this reason, the thermal insulation later is thinker at the top than in other parts.

Read More:

Portable tanker-trailer heating system

The design and manufacturing of Asphalt tanks is done in compliance with the set standards and laws governing the transportation industry.

You can get an asphalt tank trailer with either 2,3 or 4 axles based on your needs and applications. However, there are exceptions that have been made to the discharge valve and the venting aspects.

These tanks are given atmospheric venting in place of “smart vents” and allowed manual discharge instead of spring loaded closure apparatus installed with remotely controlled actuators.

4. Important Features and Specifications

The design has a 375º Tank Rating or can sometimes be set at 400º Tank Rating (adds 400 lbs). Also, it has a 3-inch and 5-inch channel. The manufacturing and fabrication is of rings continuous weld and has deep dish heads.

Jacketing System

There is a 0.04-inch jacketing on the tanker strong and durable enough to withstand many years of service. The jacketing system is exclusive that reduces the circumference seams.

It also provides high heat retention properties. It is also installed with 0.08-inch jacket heads. There is also a clip system that allows for tanker expansion and contraction.

Discharge Features

The location of the valve body assures drainage. The load heat keeps this valve free. The tanker comes with a split rear bumper installed with a sloping discharge line.

There are also optional 4-inch discharge lines, 3-inch or 4-inch gate valves, and washout and sample valve. The internal valve made with “shear” design is built according to federal standards exclusive of rollover protection.

Your tanker comes with an optional washout system. It has a 20-gallon capacity of pressurized truck air. There is an optional line to both the rear and front discharge and an optional tank made of stainless steel.

Another optional unit is the steam coils system made of 1.5-inch pipes and could be two pass, four pass or eight pass.

outlet valve

The Vent System

These are of two types:

- Etnyre Style Vent: This is a big surge chamber installed with a vent. It is insulated and has an internal vent as well as an external drain line.

- Light Weight Style Vent: This type vent into spillbox area. It is 35 lbs lighter than Etnyre Style and has an external drain line.

The Manhole Area

This is a 20-inch fast opening manhole with a single hold down cover. It is made of a standard construction as guided by the transportation laws and regulations.

The Asphalt Pump

If you want, you can get the Asphalt pump which adds to this list as an optional feature. This is specifically made for asphalt with a 200 GPM holding capacity. It is made in such a way that there are no low spots that could trap asphalt in it.

The Anti-Lock and Roll Stability Features

The anti-lock feature (ABS) of this trailer is purely an electronic system that tracks and controls the wheel speed on your trailer when braking. This entire system works with typical air brake systems. There are various versions of this system and are basically defined through the number of sensors (S) and modular relay valves (M) installed in each system type. When you find a 2S/1M, it implies that there are 2 sensors and a single modular relay valve. The standard one usually has 2 sensors and 2 modular relay valves, 2S/2M.

ABS parts

Signals from the speed sensors on the wheel are received and then processed through the electronic control unit (ECU). On condition that no wheel starts to lock, the ABS allows the usual air braking system to manage the braking. However, if a wheel begins to lock, the ECU will activate the ABS relay for the said wheel. This allows the ABS relay valve to apply and release pressure in the air chamber up to five times in a second. This cuts down wheel lock-ups and assists the driver to manage a controlled stop.

The Roll Stability Control (RSC) is a safety system of a vehicle that actively automates and intervenes should there be a high rollover risk when driving. When a rollover threat is about to occur, the system takes over and applies the trailer brakes in order to reduce the speed of the vehicle.

Contact us, get more specs now!!

5. Asphalt Tanker Best Practices

You probably are wondering about the best practices that would be beneficial in working with your asphalt tanker. Therefore, it is important to let you know about what best practices help keep your tanker serving you in the most efficient way possible.

There are a number of considerations to make when transporting asphalt. This is to make sure that the desired characteristics of the cargo are maintained throughout the transportation right from the production center to the desired destination.

This is very essential. It is therefore important to observe these practices during loading, transportation and offloading.

- Asphalt Loading Operations. Prior to leaving the production plant, there are important aspects that should be checked to maintain the quality of your product. Always do the following:

- Truck bed preparation: this should be done before loading the product. Cleaning and lubrication through the use of “release agents” must be done to keep off foreign particles. The release agent is useful in preventing the product from sticking on the truck bed. The application of the release agent should come after a thorough cleaning process. Make use of non-petroleum based release agents for lubrication. Perfect examples include soapy water or lime water. Petroleum based products must not be used due to the environmental effects of such substances as diesel fuel. Again, they have a tendency of breaking down the asphalt binder leading to a lower quality roadway.

- Avoid aggregate segregation when loading your cargo. Asphalt mixes must be placed on the truck bed in a manner that does not enhance aggregate segregation. Dropping the product mix directly from the silo in one big batch creates one pile of asphalt/bitumen mix in the truck bed. Bigger sized aggregate has a tendency to roll off this pile and gather around the base. For that reasons, recommendations are hereby made that the mix gets loaded in small bits of masses at various points within the truck bed to hamper the gathering of big aggregate in one section.

- Ensure you minimize heat loss. Asphalt cools when in transportation and this can adversely affect its characteristics on arriving at its destination and present challenges. Therefore, remember that the different product types are usually loaded at a somewhat uniform temperature. However, some of it may be lost during transportation hence causing the formation of a cool thin crust surrounding a very hot core. To prevent such things as rain, air temperature, duration of length and wind from causing heat loss, insulated truck beds and tarps that cover the load should be put in place.

- Aspalt on Transit. Planning for truck transit should be made in such a way that the transport rated in tons/hour closely matches the production rate and laywdown frequency of the plant. Traffic often interferes with the delivery rates due by tampering with the truck speed, particularly in areas that are congested. With increased travel time, many more trucks will be required to meet a certain delivery rate. Increased traffiuc leads to increased trucking costs.

- Offloading Asphalt. Asphalt needs offloading immediately after it gets to the destination to minimize the colling.

These are the most important aspects to consider to make sure that your bitumen tanker serves you the best way possible. This are the basic recommendations that will help you in managing the challenges involved in asphalt transportation from the production site to the job site. A careful management of these stages enhances quality of your product and that of your project generally.

Conclusion

Tank trailers are designed to meet specific cargo needs and therefore, it is very important for you to understand what makes an Asphalt Tanker unique for transport the type of product it does.

This guide has provided you with useful information concerning the design and structure of an Asphalt tanker that make it a suitable vehicle for the transportation of asphalt/bitumen from its production site to the work site.

A lot goes in the insulating properties of the tanker to enable the transport of the product in the desired temperature. There are important checks needed during the loading, transportation and offloading of the product that must be done to ensure a successful process.

Just like when buying any other tanker, ensure the quality of construction by ascertaining the type of materials used in the construction.